Ensure Uniform Blast Patterns and Consistent Surface Profiles on Pipe Interiors

You’re a pipe manufacturer and need to surface prepare the interior of your pipes before applying coatings, or maybe as part of your contractor business you abrasive blast the interiors of penstocks or duct work for maintenance or restoration. Manual abrasive blasting doesn’t produce a uniform blast pattern or consistent surface profiles—and you can’t have coatings failure. But the Pipe Pro XL and Spin-Blast Internal Pipe Blasting Tools help ensure consistent blasting results, keeping your jobs on schedule without rework, and protecting your reputation and bottom line.

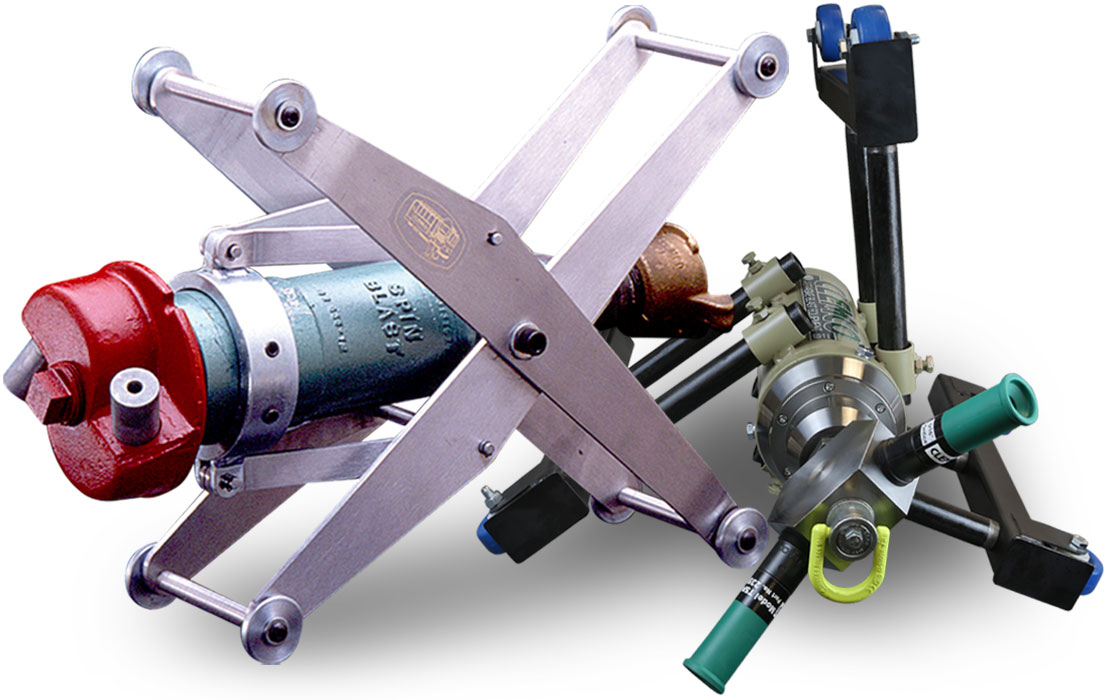

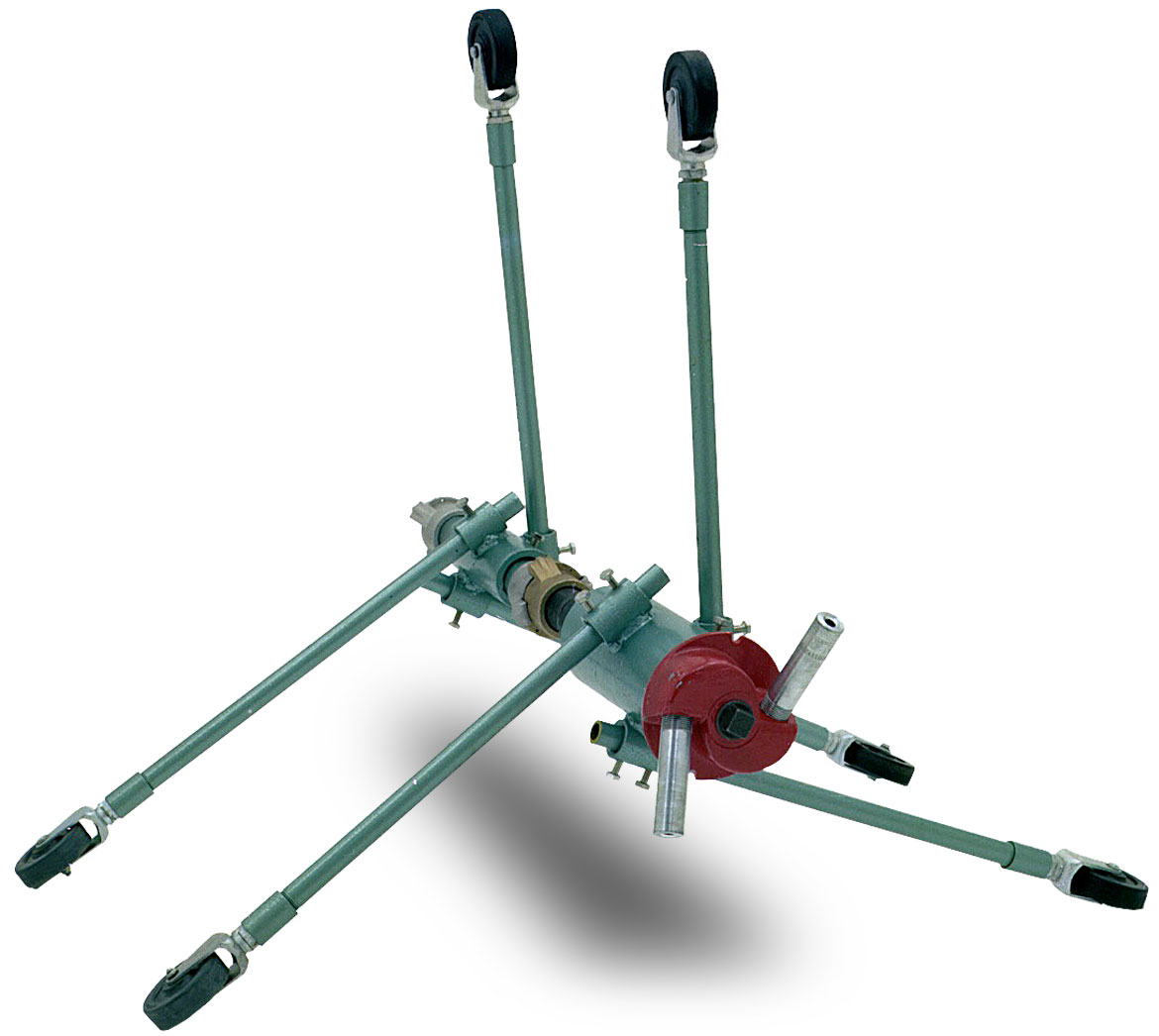

Pipe Pro XL: High-Production, Everyday-Use Pipe Blaster

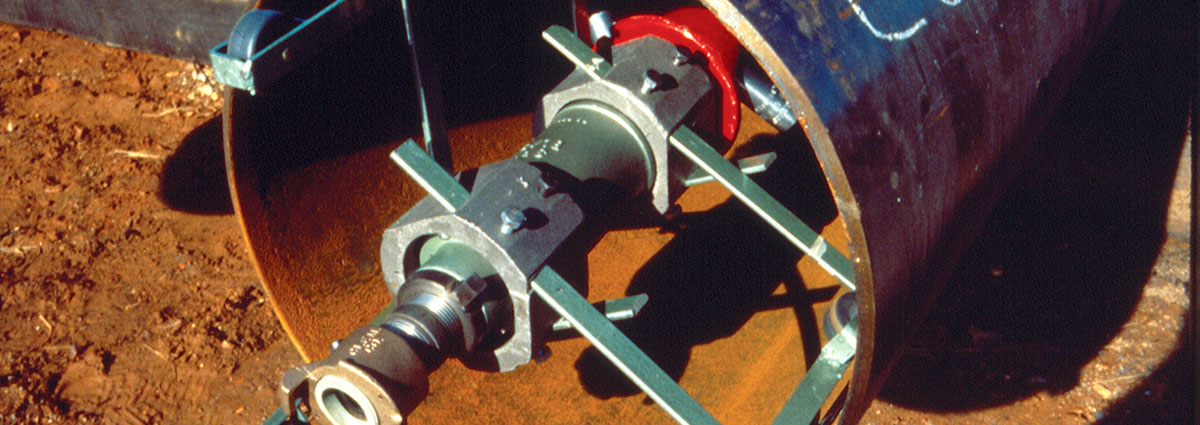

Two blast nozzles are mounted on a rotating head. A pneumatically powered air motor controls the head’s rotation speed, which operators can fine-tune by adjusting an air valve. It’s a set-it-and-forget-it, low-maintenance, easy-to-maintain, pipe-blasting system.

Two Models

- Pipe Pro XL 1631 – For pipes with 16” to 31” IDs

- Pipe Pro XL 1660 – For pipes with 16” to 60” IDs

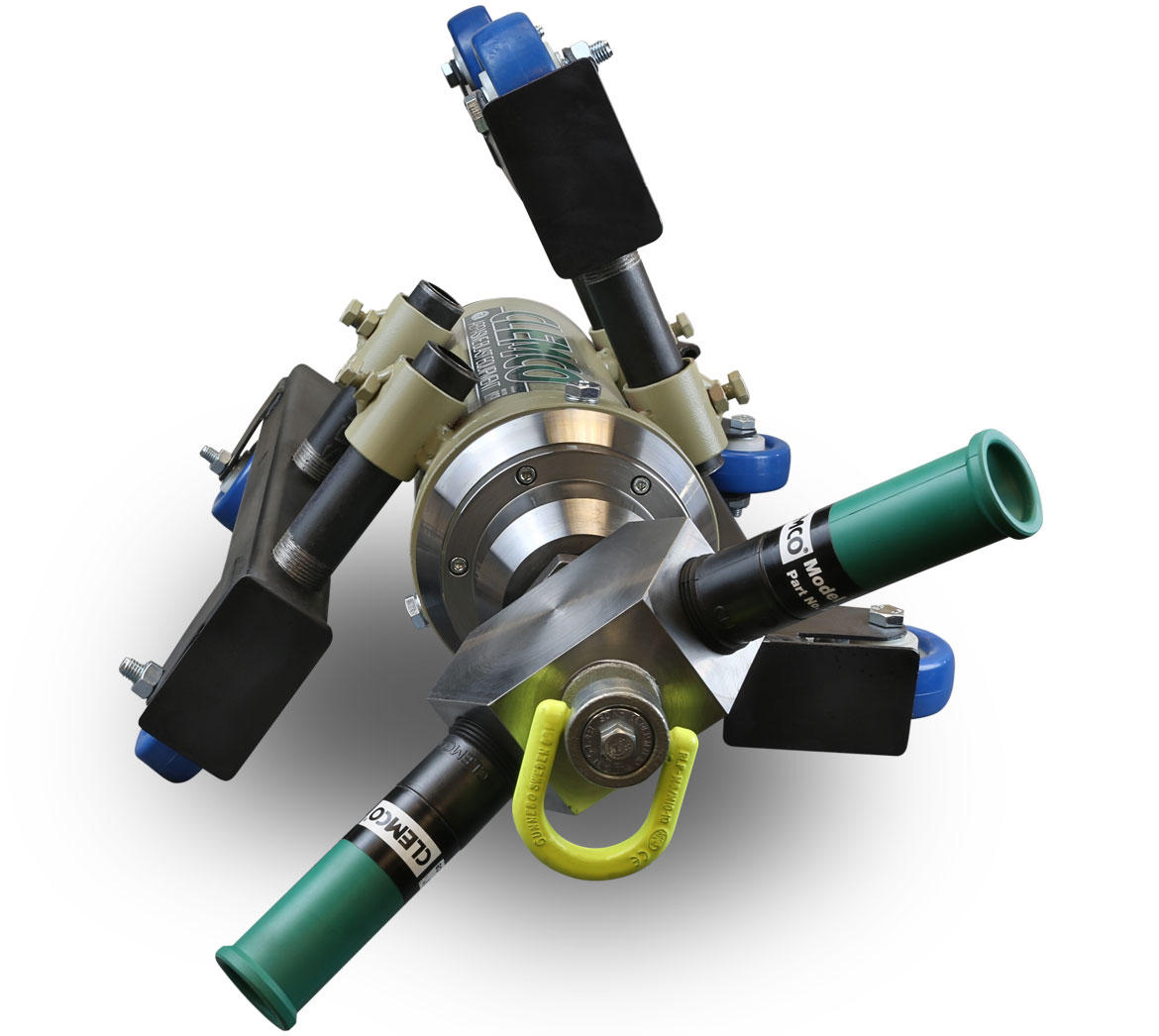

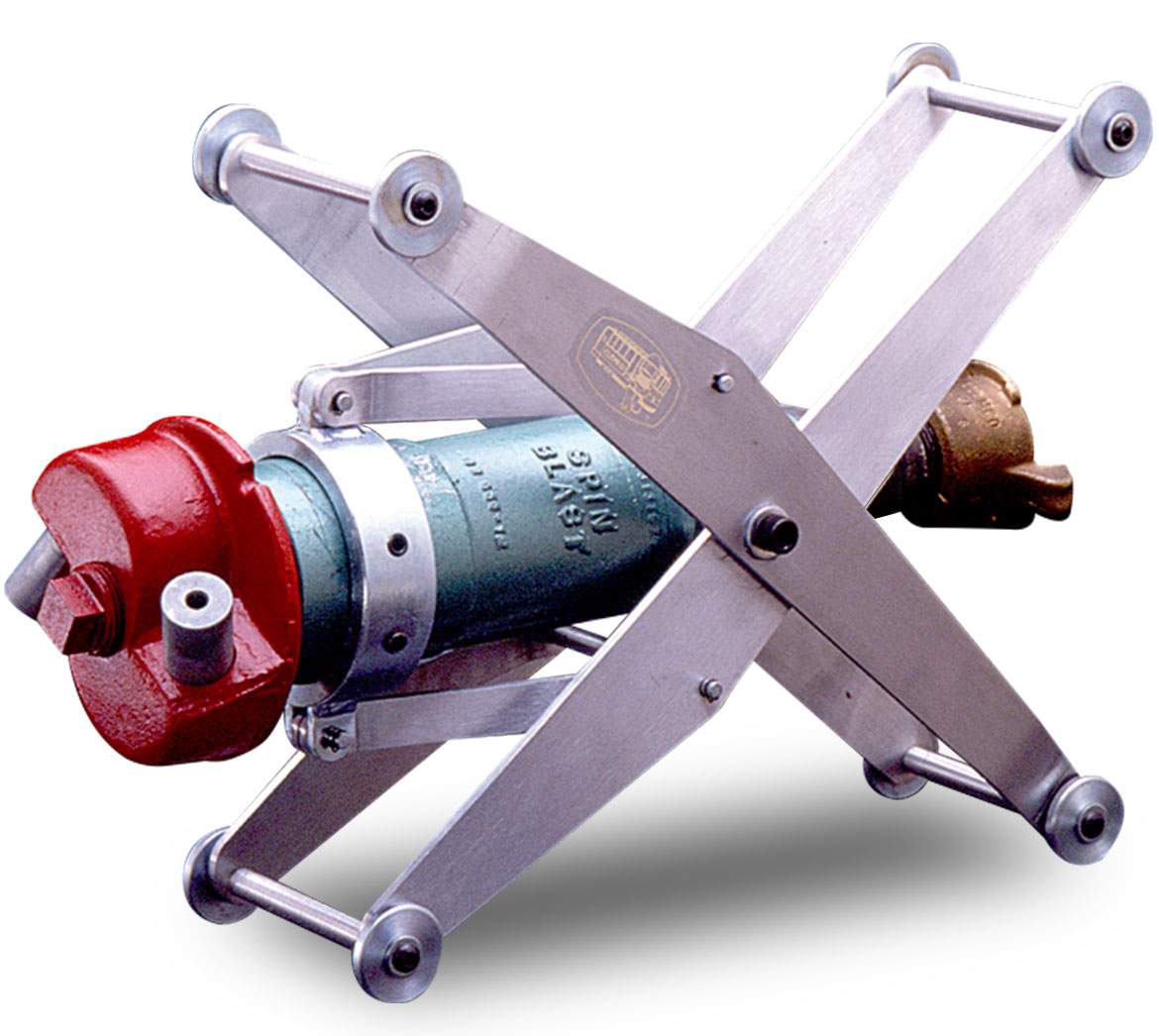

Spin-Blast: Intermittent-Use Pipe Blaster

Like the Pipe Pro XL, two blast nozzles are mounted on a rotating head. Compressed air and media passing through the blast nozzles rotate the blast head. Operators can control the head speed with a mechanical brake. It’s an efficient, simple-to-use, intermittent-use pipe blasting system.

Two Models

- Spin-Blast SB-836 – For pipes with 8” to 36” IDs

- Spin-Blast SB-3660 – For pipes with 36” to 60” IDs

Advantages: Pipe Pro XL and Spin-Blast

360° Rotating Blast Heads Help Ensure Uniform Blast Patterns and Consistent Surface Profiles

The Pipe Pro XL and Spin-Blast propel abrasive through two blast nozzles mounted on a 360° rotating blast head:

- Speeds Up Blasting – The rotating heads quickly blast pipe interiors with a uniform blast pattern throughout, even on long pipes that cannot be disassembled.

- Effectively Blasts Pipes with Large IDs – The two blast nozzles propel abrasive at high velocities to blast the pipe’s interior surface—even pipes with IDs up to 60”.

- Stay on Schedule and Avoid Rework – This high velocity blasting helps ensure consistent surface profiles so coatings adhere to blasted surfaces without failure, keeping you on schedule without rework.

- Increase Productivity – The two-nozzle system is much faster than manually blasting with one operator, increasing productivity.

Easy Setup and Operation

- Powered by Standard Blast Machines – Run the Pipe Pro XL and Spin-Blast off equipment you already have on hand, saving you time and money.

- Quick Setup – The tools easily attach to the end of your machine’s blast hose so that you can quickly be up and running.

- Centering Carriages – Quickly center the tools inside pipes, which helps them create uniform blast patterns and consistent surface profiles.

Convenience and Safety

- Save Time and Money – With a Pipe Pro XL and Spin-Blast, there’s no need for extra equipment to mechanically rotate pipes or to manually rotate pipes because these tools’ 360°rotating heads make additional equipment and procedures unnecessary, saving you money and time.

- Compact and Easy to Carry – Both tools are compact, take up little storage space, and are easy to carry from job site to job site.

- Promotes Safety – With these tools on hand, operators do not need to manual blast larger ID pipes, reducing their exposure to hazardous dust and potential accidents from working in small, confined spaces.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.