HP respirator systems for long-duration abrasive blasting or for blasting in extreme temperatures when breathing air is supplied by a high-pressure air compressor.

Abrasive blasting is difficult and dangerous. The last thing you or your crew needs on their minds is worry about their safety. Apollo HP Respirators and accessories meet OSHA safety requirements for protection from inhalation hazards and protection from rebounding abrasive. Your crew will literally breathe easier, even in extremely hot or cold temperatures, with Clemco breathing-air filters, air-flow and air-comfort devices, and CO monitor-alarms. Provide your crew with the comfort, convenience, and safety they need to fight off fatigue, stay focused, and remain productive—with Clemco’s Apollo HP Supplied-Air Respirator (SAR) Systems and accessories.

- Apollo 600 HP Supplied-Air Respirator – Maximum protection and durability combined with comfort and mobility.

- Apollo 20 HP Supplied-Air Respirator – For less frequent or demanding abrasive blasting applications without sacrificing operator safety and comfort or equipment durability.

- Air-Flow and Air-Comfort Devices – From constant-flow to heated or cooled air. Five options.

- Breathing-Air Filters –Two types of breathing air filters that remove moisture, oils, and particulates from the air supply of one to four operators.

- CO Monitor-Alarms – Alert operators if carbon monoxide enters their air supply. Three models: fixed installation, field portable, and in-helmet.

Apollo 600 High-Pressure, NIOSH-Approved, Type-CE Respirator

Your operators will be confident and comfortable during long and demanding shifts knowing that they are protected by the industry standard in safety and durability. That peace of mind increases their productivity and reduces your stress.

Comfort and Convenience

- Two Suspension System Options:

- DLX Comfort Fit – Fits like a motorcycle helmet. It features multiple soft, washable, fabric-covered pads that easily attach to the inside of the helmet shell.

- Web Suspension – Features a six-point, knob-style adjustment system and a replaceable sweatband.

- Crown-Mounted Air Baffle – Delivers ample air supply to the operator’s head and face.

- Breathing Hose Attachment – At the helmet’s center rear for a balanced feel and fit.

- Zip-In-and-Out Inner Collar – Can easily be removed for cleaning.

- Integrated Carrying Strap – Makes respirator easy to carry or hang when not in use.

- Easy Field Maintenance – Replaceable components are quick and simple to install, reducing downtime.

Performance and Durability

- Heavy-Duty Helmet – Single-shell construction. Protects operators from rebounding abrasives and overhead obstacles that can cause head, eye, or face injuries.

- Heavy-Duty, Silver-Gray Protective Cape – Protects operators from abrasive rebound while also reflecting the sun’s rays, minimizing heat absorption to help operators stay cool.

- Cape Attachment Band – Wraps around the bottom rim of the helmet shell and easily fastens or detaches with a ratchet-style buckle. Enables operators to quickly replace worn capes.

- 180° Wide View Window – Industry’s largest view window for maximum visibility.

- Quick-Change, Three-Lens Window System – Keeps Out Dust and Media:

- Sturdy Inner Lens that is held in place by a molded gasket seals out dust and media.

- Middle Lens further seals out dust and media while providing a layer of protection over the inner lens.

- Up to Three Perforated, Tear-Away Outer Lenses protect the middle lens from pitting.

Safety and Certifications

- NIOSH-approved, Type-CE supplied-air respirator (SAR) ensures your operators have safe breathing air and are compliant with safety regulations.

- OSHA assigned protection factor of 1000 x permissible exposure limit (PEL) for hazardous substances.

- ANSI Z89.1-2003 Type 1, Class G Protective Hard Hat Rating

- ANSI Z87.1-1989 Face and Eye Protection

- ANSI Z 3.19: Noise Reduction Rating (NRR): NRR 9 with DLX Comfort-Fit Suspension / NRR 8 with Web Suspension.

- Web Page: Apollo Respirator Certifications

Apollo 20 High-Pressure, NIOSH-Approved, Type-CE Respirator

Lightweight construction that offers the safety and durability of heavier respirators but that also reduces operator fatigue. Ideal for less frequent or demanding abrasive blasting applications while still fully ensuring your operators’ safety and comfort during long shifts.

Comfort and Convenience

- Two Suspension System Options:

- DLX Comfort Fit – Fits like a motorcycle helmet. It features multiple soft, washable, fabric-covered pads that easily attach to the inside of the helmet shell.

- Web Suspension – Features a six-point, knob-style adjustment system and a replaceable sweatband.

- Molded-In Carrying Handle – Makes respirator easy to carry around job sites.

- Easy Field Maintenance – Replaceable components are quick and simple to install, reducing downtime.

Performance and Durability

- Sturdy Helmet – Single-shell construction. Protects operators from rebounding abrasives that can cause eye or face injuries.

- Heavy-Duty Protective Cape – Protects operators from abrasive rebound.

- Rectangular Window – Provides clear field of vision.

- Quick-Change, Three-Lens Window System – Keeps Out Dust and Media:

- Sturdy Inner Lens that is held in place by a molded gasket seals out dust and media.

- Middle Lens further seals out dust and media while providing a layer of protection over the inner lens.

- Up to Three Perforated, Tear-Away Outer Lenses protect the middle lens from pitting.

Safety and Certifications

- NIOSH-approved, Type-CE supplied-air respirator (SAR) ensures your operators have safe breathing air and are compliant with safety regulations.

- OSHA assigned protection factor of 1000 x permissible exposure limit (PEL) for hazardous substances.

- ANSI Z87.1-1989 Face and Eye Protection

- ANSI Z 3.19: Noise Reduction Rating (NRR): NRR 9 with DLX Comfort-Fit Suspension / NRR 8 with Web Suspension.

- Web Page: Apollo Respirator Certifications

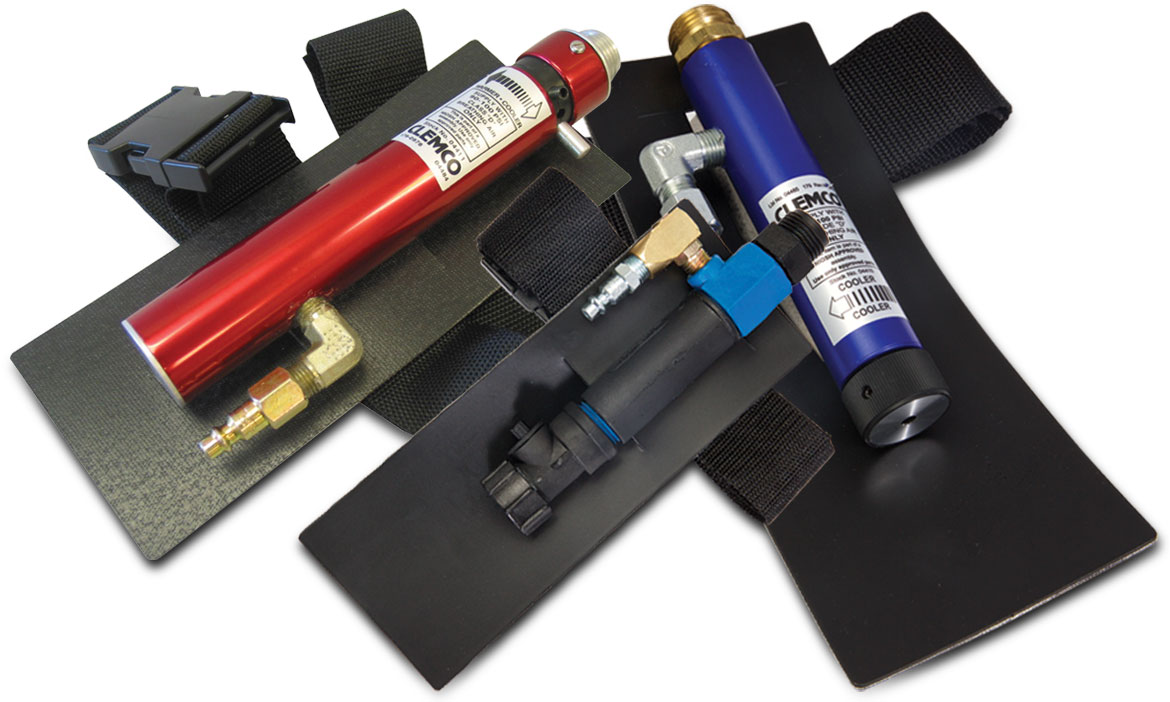

Air-Flow and Air-Comfort Devices

Two Air-Flow Devices: For Abrasive Blasting in Moderate Temperatures

Clemco air-flow devices allow operators to focus on the work at hand rather than worrying if enough breathing air is reaching their Apollo 600 or 20 HP Respirators, which helps them remain productive and safe:

- Constant Flow Connector (CFC) – Ensures that a fixed volume of breathing air reaches operators at a maximum flow rate. Flow rate is not adjustable.

- Air Control Valve (ACV) – Enables operators to control air volume to within a preset range of 7 to 15 CFM, so they can customize air flow to their needs.

Three Air-Flow/Air-Comfort Devices: For Blasting in Hot and/or Cold Temperatures and for Adjusting Air Volume

Extreme temperatures, hot or cold, can contribute to extreme fatigue. Clemco air-flow/air-comfort devices help operators stay focused and comfortable in their Apollo 600 or 20 HP Respirators while working in extremely hot or cold temperatures, which reduces their fatigue and improves their productivity.

- Clem-Cool Air Conditioner (CCAC) – Economical device that enables operators to cool incoming air by as much as 50° F. Unit is disposable. Technical Data Sheet

- Cool Air Tube (CAT) – Enables operators to cool incoming air by as much as 50° F. Unit has replaceable parts for long service life. Technical Data Sheet

- Climate Control Tube (CCT) – Enables operators to cool or warm incoming air by as much as 40° F. Unit has replaceable parts for long service life. Technical Data Sheet

CPF In-Line Breathing-Air Filters

Air compressors frequently take a beating and often are not well-maintained. As a result, oils and particulates can enter their air lines, potentially creating inhalation hazards.

Safety and Comfort

- Moisture, Oil, and Particulates Larger Than 0.5 Micron – Clemco CPF Breathing-Air Filters ensure that mists (including oil mists), water vapor, and particulates greater in size than 0.5 micron are removed from operators’ breathing air before it enters their respirators.

- Meets OSHA Requirements – CPF Breathing Air Filters meet OSHA requirements and feature a NIOSH-mandated point of attachment.

- Multistage Filtration System – Includes activate charcoal that eliminates odors and improves the “taste” of breathing air.

Two Models

- CPF 20 – For use with up to two operators

- CPF 80 – For use with up to four operators

Carbon Monoxide (CO) Monitor-Alarms

Breathing air contaminated with carbon monoxide can cause serious, even fatal, injuries. Carbon monoxide has no odor, color, or taste—so by the time operators are aware of its presence, it may be too late. Protect your crew’s safety and give them peace of mind so that they can focus undistracted on their work with Clemco CO Monitor-Alarms that detect carbon monoxide in concentrations of at least 10 parts per million (ppm) in respirator air supplies.

Three CO Monitor-Alarms

- CMS-1 – Industrial Use: Fixed installation, typically wall mounted, and capable of monitoring air for multiple respirators. Ideal for industrial use such as in blast rooms. Unit triggers a warning light and audible alarm. Optional remote alarm. Unit’s threshold can be reset from 10 ppm to 5 ppm. Technical Data Sheet

- CMS-2 – Field Portable: Designed for most outdoor, mobile blasting applications. Capable of monitoring air for multiple respirators. Unit triggers a warning light and audible alarm. Optional remote alarm. Its threshold is set at 10 ppm.

Technical Data Sheet - CMS-4 – In-Helmet Installation: Compact, one-of-a-kind design quickly attaches inside the helmet of an Apollo 600 or 20 HP Respirator. Enables an operator to self-monitor his/her CO exposure. Unit triggers audible, visual and vibratory alarms, and its threshold can be reset from 10 ppm to 5 ppm. Technical Data Sheet

Videos

CMS-4 Setup Guide: Part 1

[arve url=”https://vimeo.com/351489631″ mode=”lazyload-lightbox” thumbnail=”23607″ title=”CMS-4 Setup Guide: Part 1″ /]

CMS-4 Setup Guide: Part 2

[arve url=”https://vimeo.com/350312861″ mode=”lazyload-lightbox” thumbnail=”23607″ title=”CMS-4 Setup Guide: Part 2″ /]

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.