Your Job Just Got Easier

You need a bulk blaster that can keep up with you, not a low-quality machine that you push to the max for minimum results. Instead, invest in a Pro-Series Big Clem—bulk blasters that give you what you need:

- 175-PSI Rated Pressure Vessels—The industry’s highest rating for bulk blasters.

- The Industry’s Fastest Refill Cycle—20% faster from depressurization to repressurization.

- Improved Super Sack Rack—For even faster and safer abrasive refills.

- GritWizard Abrasive Metering Valve—Handles all common media. From ALOX to glass bead and everything in between. No need to stock multiple valves and spares.

- Pop-Up Valves—Time tested for decades as the industry’s safest method for sealing pressure vessels.

- More Features—Loads of other time-saving, productivity-enhancing features.

Pro-Series Big Clem Bulk Blasters

[arve url=”https://vimeo.com/684233730?share=copy” title=”Pro-Series Big Clem Bulk Blasters” mode=”lazyload” thumbnail=”23303″ loop=”no” muted=”no” /]

Maximize Your Productivity

Pressure loss kills productivity, which is why Pro-Series Big Clems have:

175-PSI Rated Pressure Vessels

The industry’s highest rating for bulk blasters.

Optimized Plumbing Configuration

Delivers maximum pressure to the nozzle, boosting operator productivity.

Dual 3” Air Inlets

- Eliminates need for additional field plumbing.

- Easily supports multiple operators and larger nozzles.

Less Time Setting Up, More Time Blasting

Every second your crew isn’t blasting, you’re losing time—and profit. That’s why Pro-Series Big Clems have:

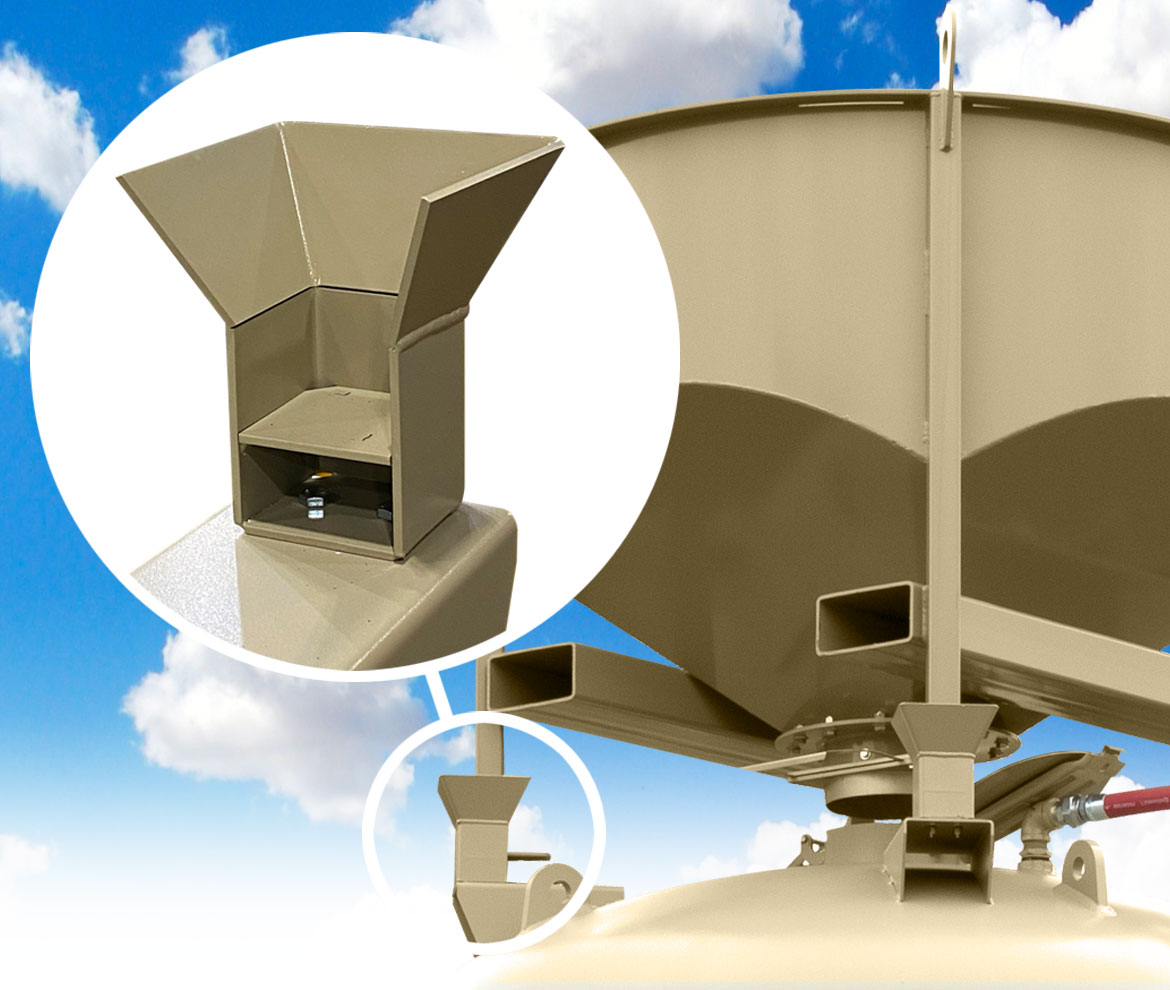

Improved Super Sack System

Circular Designed Hopper with Sloped Sump: Allows media to flow faster and empty more completely.

Redesigned Mountings: Simplifies aligning the rack onto the pot.

Media Discharge Valve

- Easier and safer for operators to setup the super sack system.

- Reduces media loss due to spills during refill cycle.

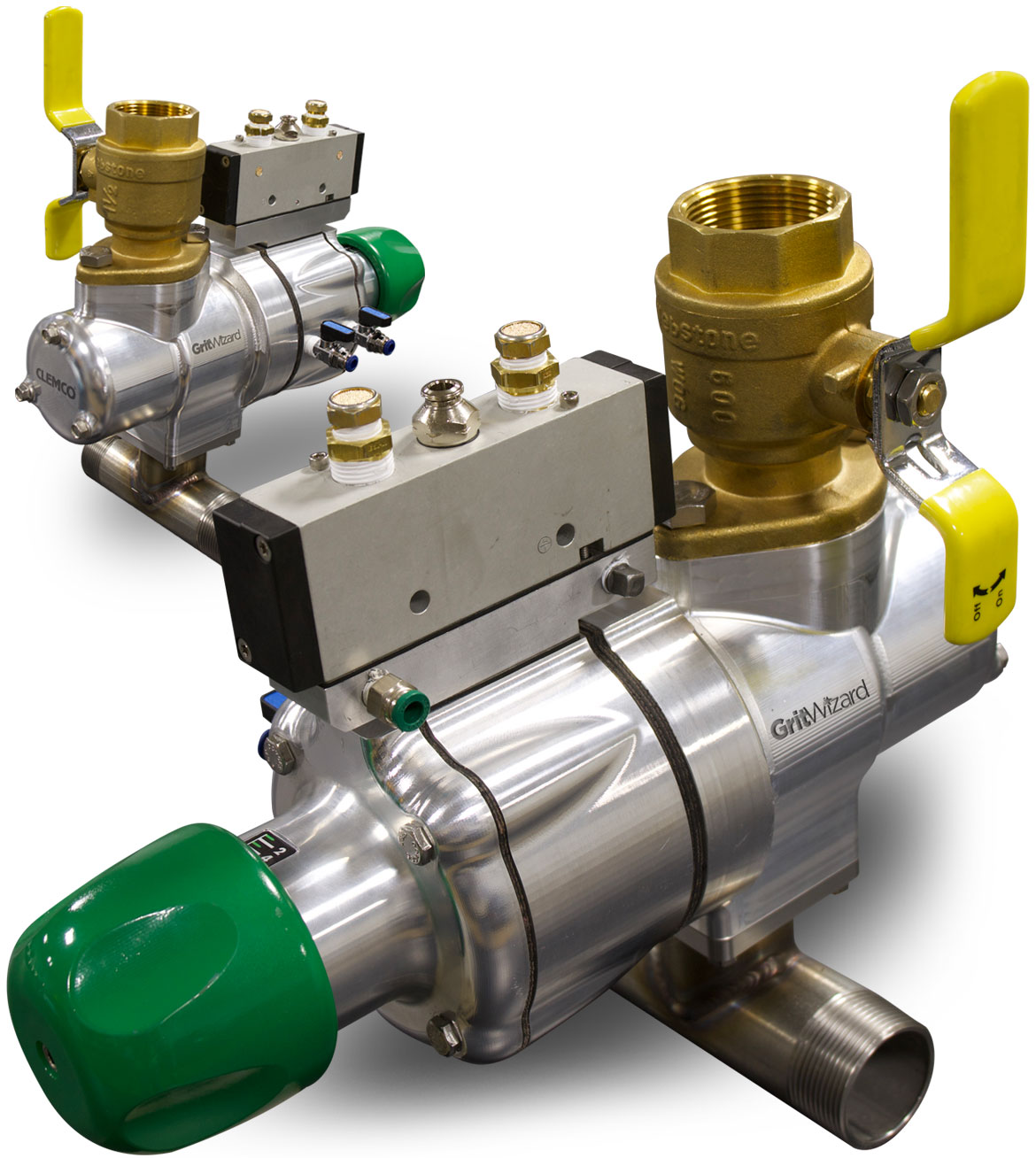

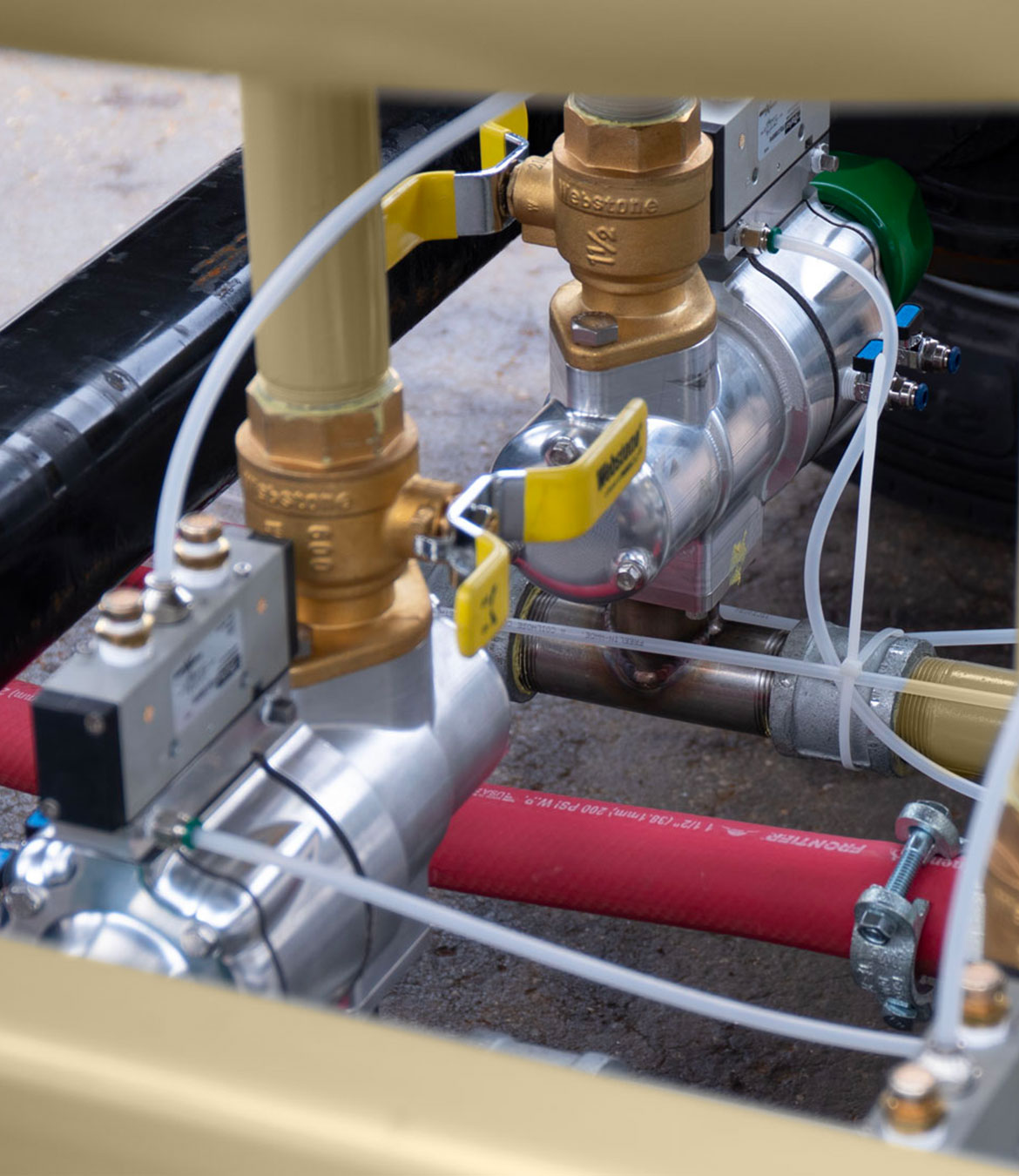

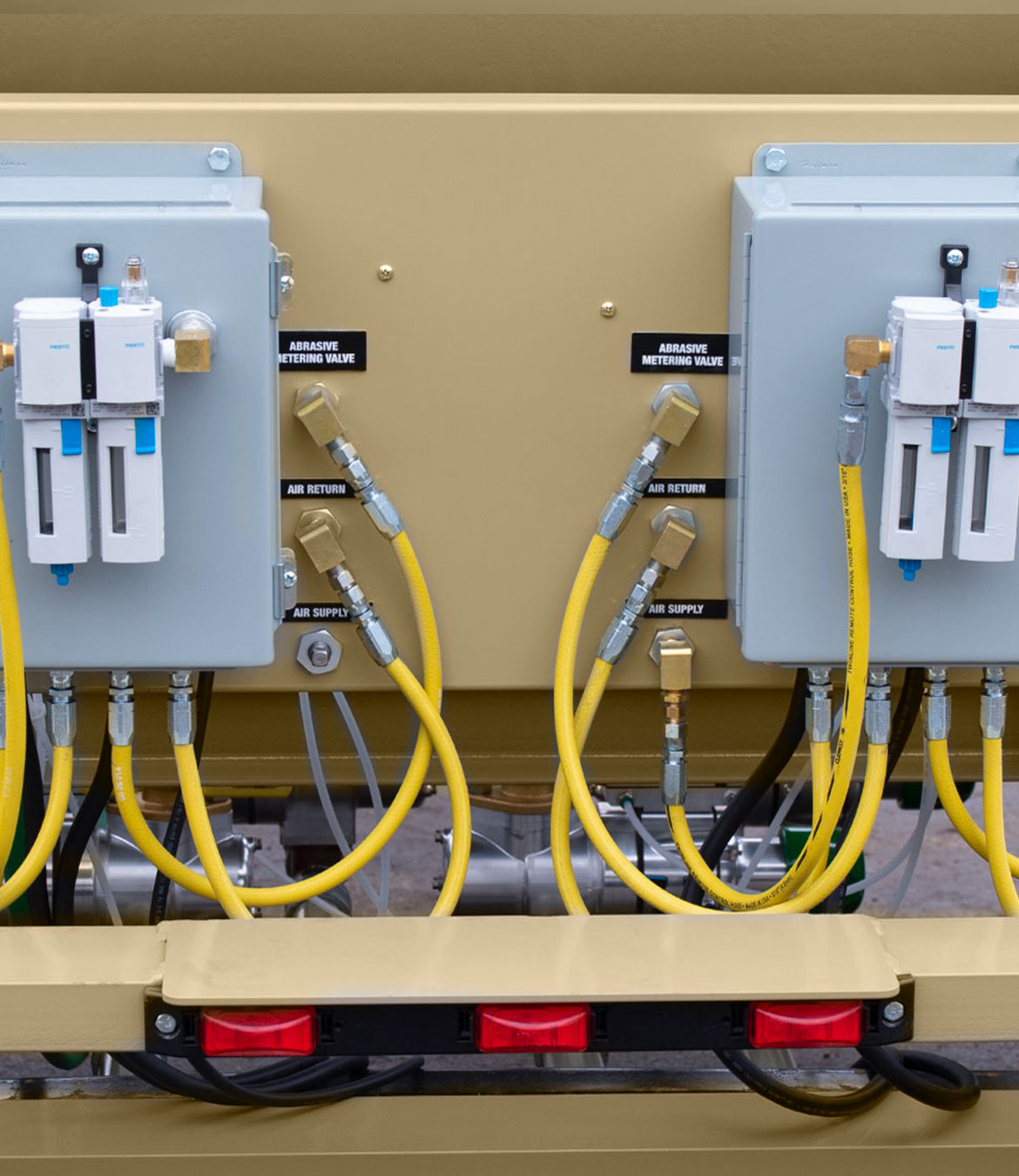

One Valve Does It All: GritWizard

Versatility

- All Common Media—From ALOX to glass bead and everything in between. No need to stock multiple valves and spares. You only need the GritWizard.

- Applications—Pressure hold or pressure-release. Prnuematic or electric. The GritWizard works with them all.

Performance

- Precision Metering—Optimal media flow ensures a consistent surface finish while maximizing productivity.

- Adjustments While Blasting—Adjust media flow while valve is actuated.

Simplicity

- Easy Installation—Less time setting up means more time blasting.

- Simple Maintenance and Repairs—60% fewer wear components. 60% less complexity for you.

Durability

- The GritWizard Lasts up to 12 Times Longer—Don’t waste money on valves that wear out and wear you down. Invest in a GritWizard

Pop-Up Valves: The Safest Option for Decades

Simple. Time Proven. Safe.

Pop-up valves have been used in smaller blast machines throughout the industry by all manufacturers for decades—because they are the safest option.

No Guessing

After a pot pressurizes, its pop-up valve seals. After it depressurizes, the valve drops. No guessing, and your crew can refill the pot right away.

Enhanced Safety = Peace of Mind

The safety of your blasting crew matters to you. Pro-Series Big Clems ensure their safety with:

Outlet Muffler

Reduces noise levels below 90 dBa, so you are OSHA compliant.

Ergonomically Designed Abrasive Cutoff Switch

Safer for operators to control blast hose when turning abrasive flow on and off.

Lifting Eyes and Forklift Pockets

Easy access locations simplify crane and forklift handling.

Tie-Down Lugs

Straightforward method for securing machines for transport.

More Convenience, Less Aggravation

Equipment maintenance on the job site shouldn’t be difficult. Pro-Series Big Clem’s make it easier with:

Unobstructed Access to Metering Valves

- Easy access for quick adjustments to media flow.

- Speeds up field and routine maintenance

Centralized Control Panel

Uncluttered design simplifies setup, troubleshooting, and hooking up more operators.

Industry’s Largest Manway

Standard 20% larger opening.

Operator Entry Handle

Easy entry into the pressure vessel through the manway.

Manway Door Hanger

Frees the operator’s hands to secure crab assembly.

Specifications: WxHxD

The Pro-Series Big Clem Abrasive Bulk Blasters comes in 3 different sizes and 4 different configurations.

Highway Towable

- 60 cuft: 94 x 124 x 180

- 120 cuft: 94 x 118 x 180

- 160 cuft: 90 x 119 x 180

Yard Towable

- 60 cuft: 90 x 124 x 180

- 120 cuft: 90 x 118 x 180

- 160 cuft: 90 x 118 x 180

Skid Mounted

- 60 cuft: 62 x 108 x 109

- 120 cuft: 75 x 116 x 109

- 160 cuft: 87 x 113 x 110

Stationary

- 60 cuft: 62 x 98 x 85

- 120 cuft: 75 x 112 x 99

- 160 cuft: 87 x 117 x 109

Videos

Big Clem Electric: Setup Guide

[arve url=”https://vimeo.com/683604363″ mode=”lazyload-lightbox” thumbnail=”23370″ title=”Big Clem Electric: Setup Guide” /]

Big Clem Electric: Startup Guide

[arve url=”https://vimeo.com/683618635″ mode=”lazyload-lightbox” thumbnail=”23370″ title=”Big Clem Electric: Startup Guide” /]

Big Clem Pneumatic: Setup Guide

[arve url=”https://vimeo.com/786360944″ mode=”lazyload-lightbox” thumbnail=”23370″ title=”Big Clem Pneumatic: Setup Guide” /]

Big Clem Pneumatic: Startup Guide

[arve url=”https://vimeo.com/786379056″ mode=”lazyload-lightbox” thumbnail=”23370″ title=”Big Clem Pneumatic: Startup Guide” /]

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.