Ensure Uniform Blast Patterns and Consistent Surface Profiles on Pipe Interiors

Blasting pipe interiors for recoating is a big source of your abrasive blasting rehab and maintenance business, or you could be a pipe manufacturer who relies on small diameter water pipes and other infrastructure piping and tubing for revenue. You need a tool that can blast the interior of pipes with small IDs more effectively and faster than mechanical or manual methods that require rotating pipes. You need Clemco’s Hollo-Blast and Hollo Blast Jr. Internal Pipe Blasters, abrasive blasting tools that help ensure uniform blast patterns and consistent surface profiles on pipe interiors. Prevent coatings failure, keep on schedule without rework, and protect your reputation and bottom line—with Clemco internal pipe blasting equipment.

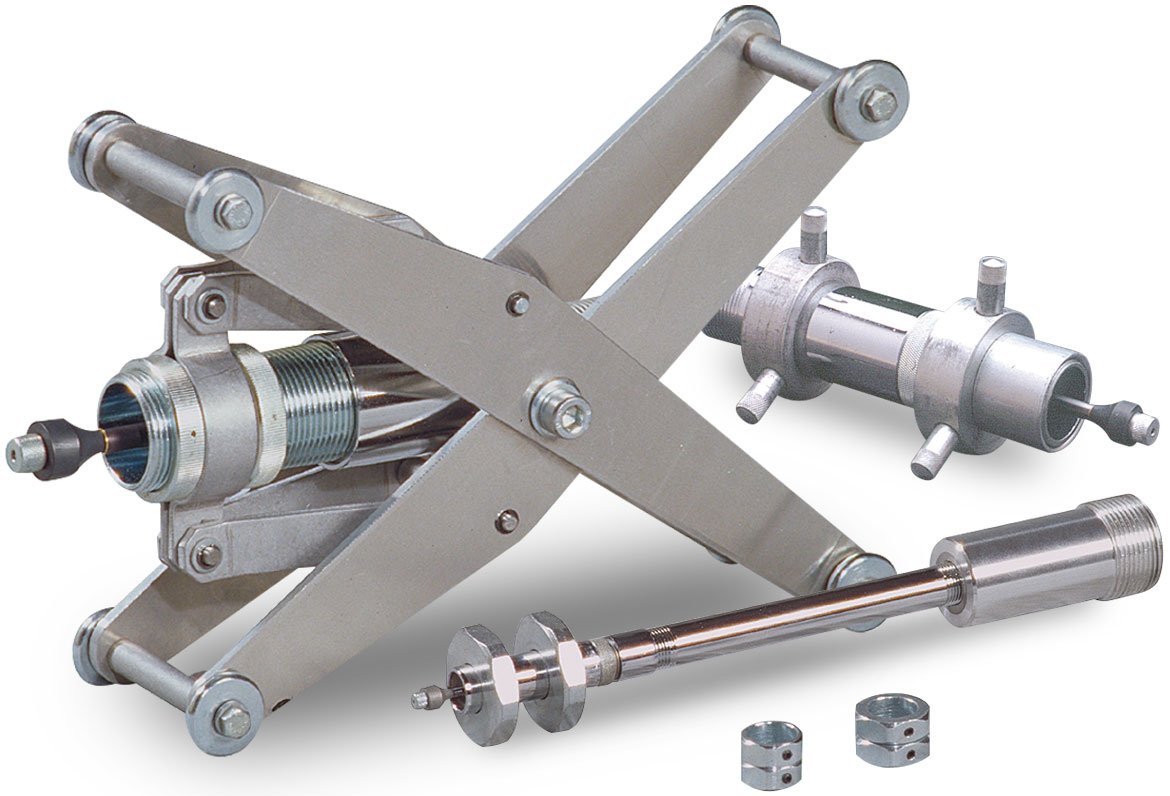

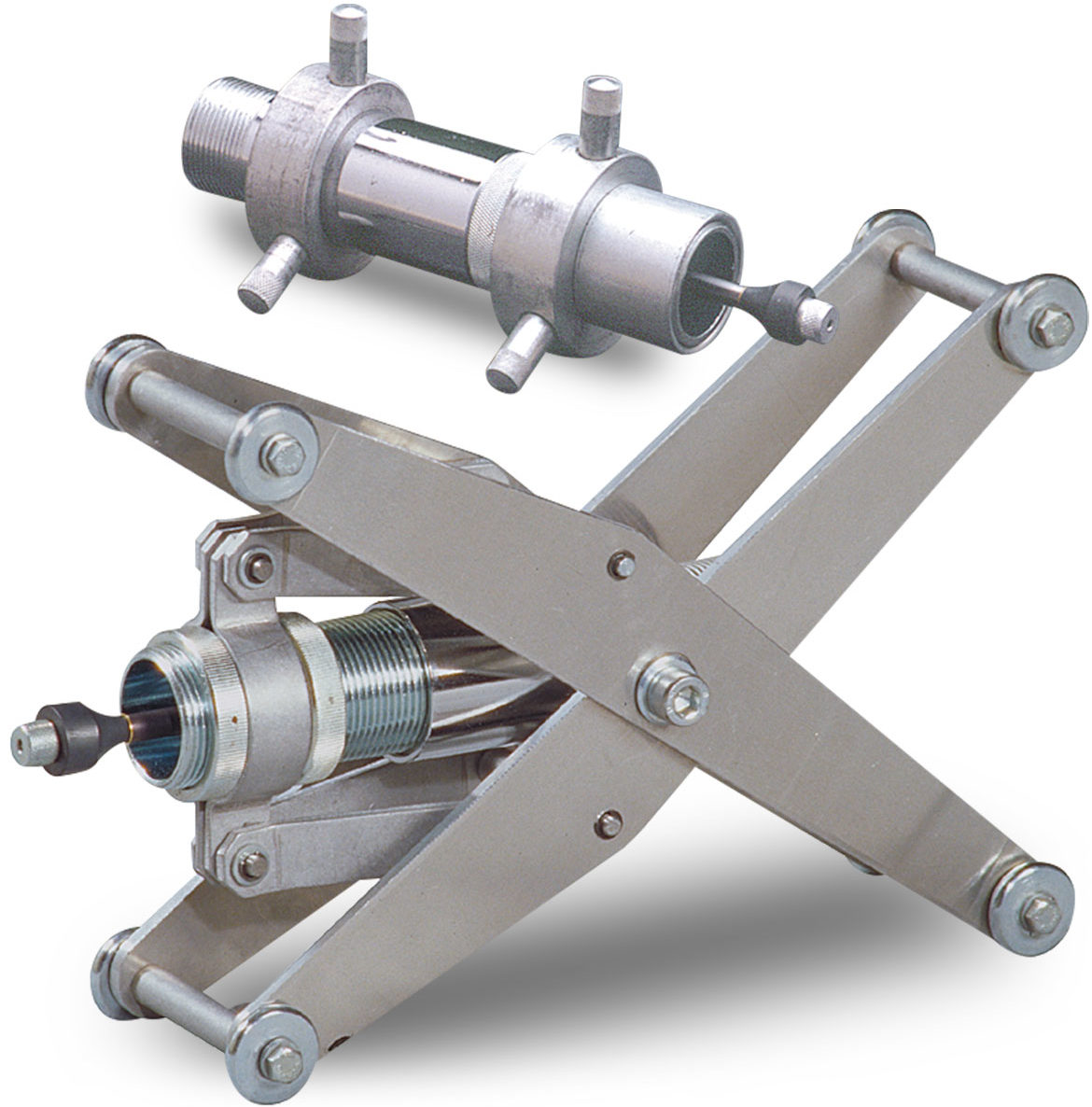

Hollo-Blast: For Pipes with 2” to 12” IDs

Abrasive hits a deflection tip and fans out 360°.

Six Models

With tungsten carbide tip and sleeves. For common abrasives:

- Without nozzle

- With 1/2” nozzle

- With 5/8” nozzle

With boron carbide tip and sleeves. For aggressive abrasives:

- Without nozzle

- With 1/2” nozzle

- With 5/8” nozzle

Two centering carriages available:

- HBC-1 for pipes 3”- 5” IDs

- HBC-2 for pipes 5”- 12” IDS

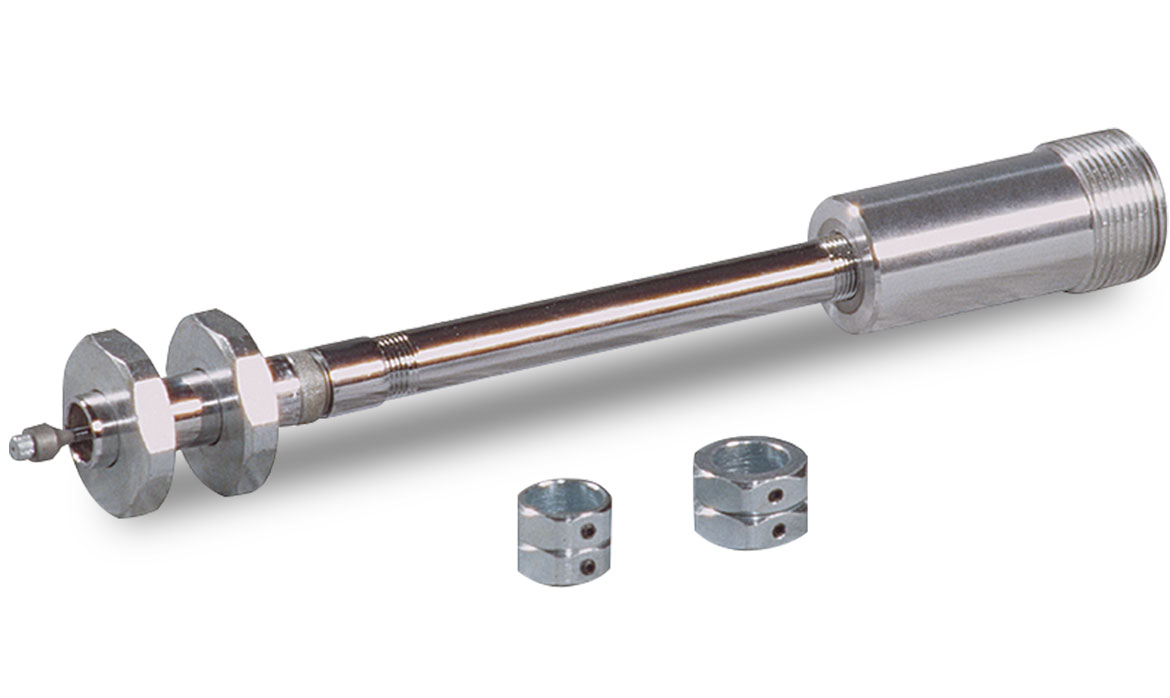

Hollo-Blast Jr.: For Pipes with 3/4” to 2” IDs

Same deflection-tip system as the Hollo-Blast but designed for smaller ID pipes, and the Hollo-Blast Jr. comes standard with a centering carriage for 3/4” – 2” IDs.

Two Models

- With reducing collar

- Without reducing collar

Advantages: Hollo-Blast and Hollo-Blast Jr.

Deflection Tips: Help Ensure Uniform Blast Patterns and Consistent Surface Profiles

The Hollo-Blast and Hollo Blast Jr. operate by propelling abrasive against a deflection tip:

- Increase Productivity – Abrasive fans out 360°, enabling the Hollo-Blast and Hollo Blast Jr. to quickly blast pipe interiors with a uniform blast pattern throughout, even on longer pipes that cannot be disassembled.

- Stay on Schedule and Avoid Rework – This process helps ensure consistent surface profiles so that coatings adhere to blasted surfaces without failure, keeping you on schedule without rework.

- Save Time and Money – There’s no need when blasting with a Hollo-Blast or Hollo-Blast Jr. for extra equipment to rotate pipes or to manually rotate pipes because the 360°deflection tips make this unnecessary, saving you money and time.

- Speeds Up Blasting – The deflection-tip system is faster than manually blasting, so you get more blasting done in less time—with higher-quality results.

Easy Setup and Operation

- Compact and Easy to Carry – The Hollo-Blast and Hollo-Blast Jr. are lightweight, take up little storage space, and are easy to carry from job site to job site.

- Powered by Standard Blast Machines – Run them off equipment you already have on hand, saving you time and money.

- Quick Setup – The tools easily connect to a pipe lance, which next can be attached to the end of your machine’s blast hose so that you can quickly be up and running.

- Easy Service and Maintenance – The Hollo-Blast and Hollo-Blast Jr. are built with limited wear components, making them easy to service and maintain.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.