About Clemco

Clemco Industries Corporation is the global leader in developing and delivering advanced surface preparation blasting and shot peening solutions tailored to meet each customer’s specific needs. Our unmatched understanding of abrasive blasting applications, coupled with our end-to-end approach of discovery, collaboration, development, and implementation that we call the Ideation 2 Realization™ Process, results in innovative engineered solutions delivered on time and fully supported. Together with our customers, we help ensure a safer, more productive world.

From our corporate headquarters and 150,000 square foot research and production center in Washington, Missouri, our world-class team of engineers, designers, customer support professionals and manufacturing experts design, assemble, integrate, and deliver a full range of blast machines, blast and peening cabinets, fully engineered blast rooms and blast accessories that incorporate advanced automation, controls, and robotics to safely prepare a wide variety of steel and metallic surfaces.

Our solutions incorporate specialty blast technologies, vacuum and recovery systems, automated blast systems, portable blast machines, automated surface preparation systems, customer engineered blast systems and hand cabinets. Through our international headquarters in Munich and distribution center in Singapore, we bring our products and solutions to our customers across the globe directly and efficiently.

We target fulfilling the unmet needs of our customers, particularly where the quality of surface preparation and finish is important. Our in-house design, manufacturing, project management, and customer and technical support capabilities ensure that each customer’s job gets done gets safely, productively and at the quality levels required. At the same time, our solutions lower the ownership cost and maximize the ease of use and maintenance of our equipment.

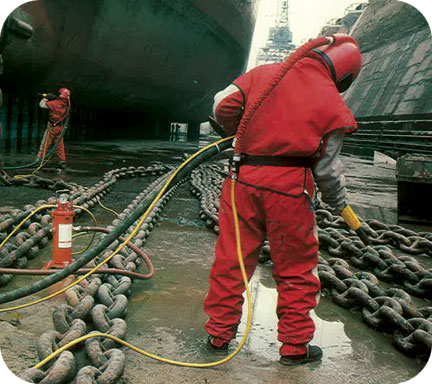

As the productivity, environmental and regulatory requirements of our customers constantly evolve, we continuously develop data-driven scenarios to better understand each customer’s specific needs and ensure a superior customer experience. This value-driven approach has enabled us to expand our business focus in recent years to include aerospace, energy, firearms, medical devices, heavy equipment, bridges, pipelines, shipyards, water towers and other industries.

To support this expanded customer focus, we are accelerating the development of new products and technology-driven solutions for customers with critical standards for finish, reliability and safety. In 2020, we introduced the new Pulsar Plus blast cabinet and in March 2022 we introduced the Big Clem Pro Series Bulk Blasters, Grit WizardTMPressure Hold Metering Valve, and Munkebo Portable Vacuum Systems. We will continue to invest in developing and delivering innovative solutions that meet the evolving needs of our expanding customer base globally.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.