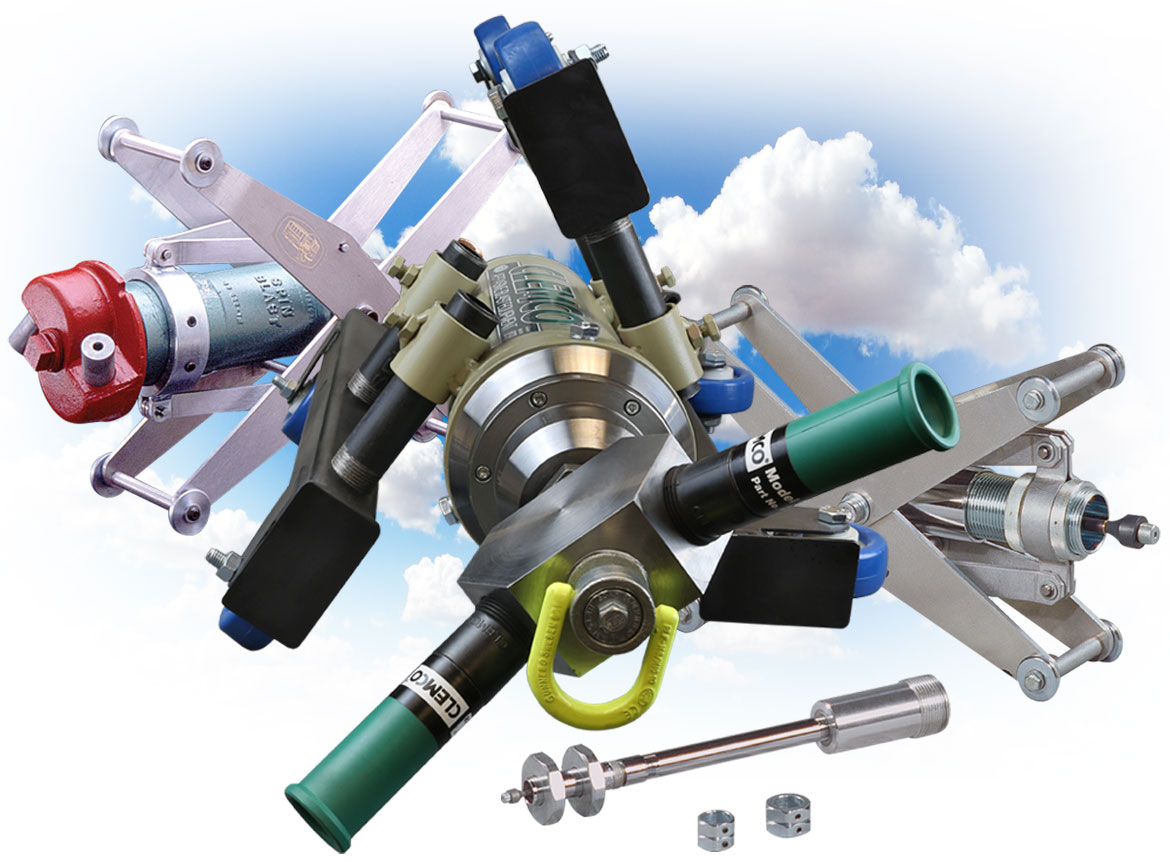

Abrasive Blast Machines, Wetblast Machines, and Specialty

Blasting Tools for Your Surface Preparation Jobs

Today you could be supervising a half-dozen operators, or a crew of one (You!). You could be surface finishing,

removing corrosion, dry blasting, or wetblasting. Maybe you are surface preparing pipe interiors for recoating, or you need a lightweight suction blaster for small or touchup jobs. Whatever the job, you have to be able to do it all—at a moment’s notice—because you’re running a business and you have more on your plate than just the abrasive blasting job in front of you.

Whatever the job—you need the right equipment.