Avoid Unplanned Downtime, Ensure Safety, Reduce Media Costs, and Keep Productivity High

Quality matters. The quality of your work, of your blast machines, and of their replacement parts and spares. Clemco manufactures OEM metering valves and remote controls as replacement parts and spares, designed to the specifications of your Clemco blast machine. These accessories help prevent unplanned downtime, hits to your productivity, and rising media costs caused by increased media consumption, all of which can be caused by worn components. Protect the safety of your operators, protect your reputation for quality work, by using Clemco OEM metering valves and remote controls.

- Five manual metering valves

- Three pneumatic metering valves

- RLX pneumatic and electric remote controls

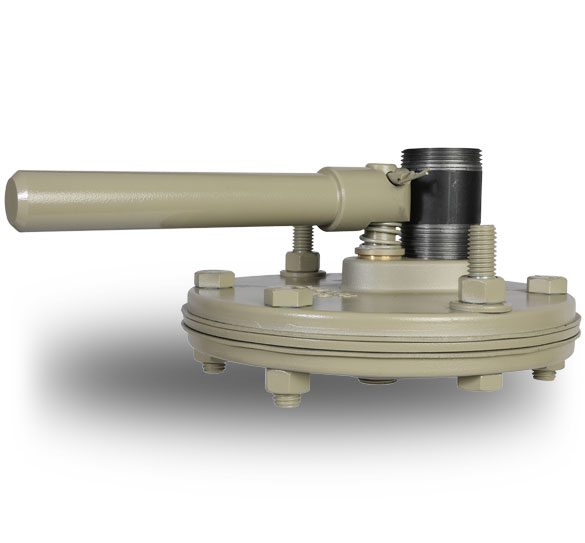

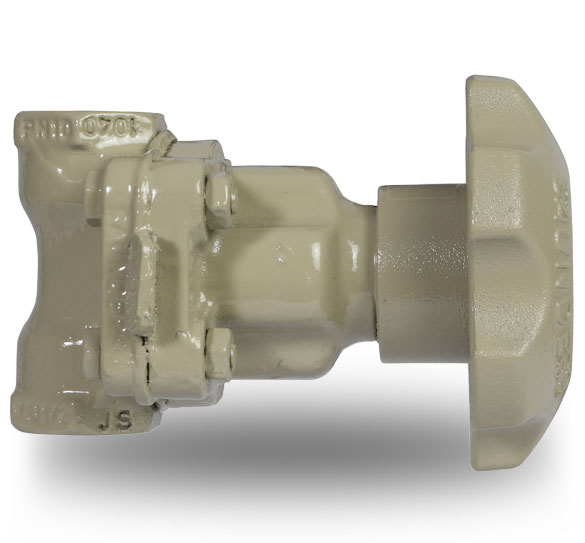

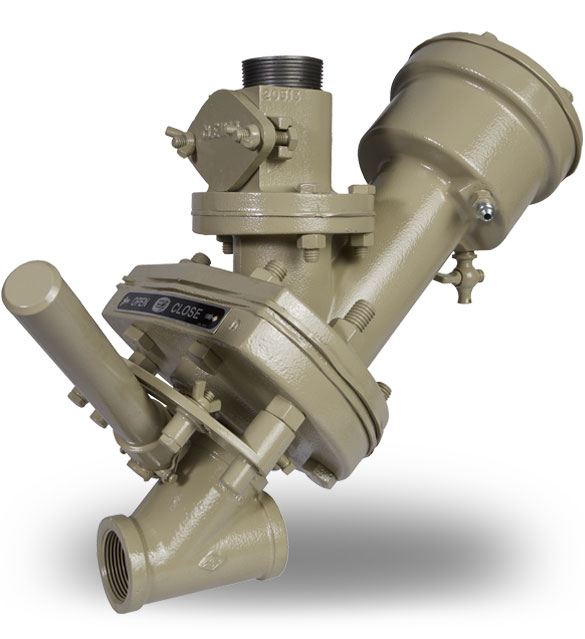

Manual Metering Valves

For pressure-release applications when operators are frequently blasting for long durations with short runs of blast hose at ground level. Clemco offers five manual metering valves to fit your application’s requirements and your pot’s design.

- Manual Quantum Valve (MQV-Pro) – For use with all common media in 2-cuft and larger blast machines.

- Flat Sand Valve (FSV) – For use with expendable mineral and slag abrasives in 2-cuft and larger blast machines.

- Manual Sand Valve (MSV) – For use with expendable mineral and slag abrasives in 1/2-cuft and 1-cuft blast machines

- Lo-Pot Valve (LPV) – For use with expendable mineral and slag abrasives in Clemco’s 6-cuft Classic Lo-Pot. The Lo-Pot Valve’s compact design accommodates the Lo-Pot Blast Machine’s low ground clearance.

- Lightweight Media Valve (LMV) – For use with bicarbonate soda, glass bead, and agricultural media in Clemco’s Soft King and Pool Pal Blast Machines.

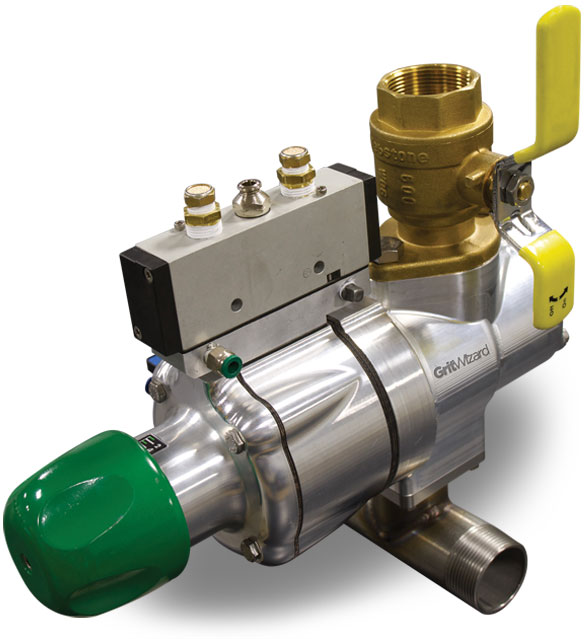

Pneumatic Metering Valves

For pressure-release and pressure-hold applications, frequently used in applications with multiple lengths of blast hose or when operators are blasting on scaffolding. Clemco Pneumatic Metering Valves come equipped with abrasive cutoff capability that enables operators to shut off abrasive flow during blasting, which allows operators to quickly clear a blast hose to eliminate slugging on the next startup. Clemco offers three pneumatic metering valves to fit your media and application requirements.

- Auto Quantum Valve (AQV) – For use with all common media in pressure-release applications. Designed for 3-cuft and larger blast machines.

- Sentinel Valve – For use with fine-mesh media. The Sentinel is commonly installed on pressure-release blast cabinets. Technical Data Sheet

- GritWizard® Valve – For pressure-hold and pressure-release applications. Designed for 3-cuft and larger blast machines.

- Use with all common media, out-of-the-box without modifications.

- Its optimal media flow ensures a consistent surface finish while maximizing productivity.

- You can adjust media flow while the GritWizard is actuated, so you don’t waste time and media.

- It’s simple to maintain and repair, with 60% fewer wear parts.

GritWizard® Abrasive Metering Valve Testimonial

[arve url=”https://vimeo.com/704705303?share=copy” title=”GritWizard Abrasive Metering Valve Testimonial” mode=”lazyload” loop=”no” muted=”no” /]

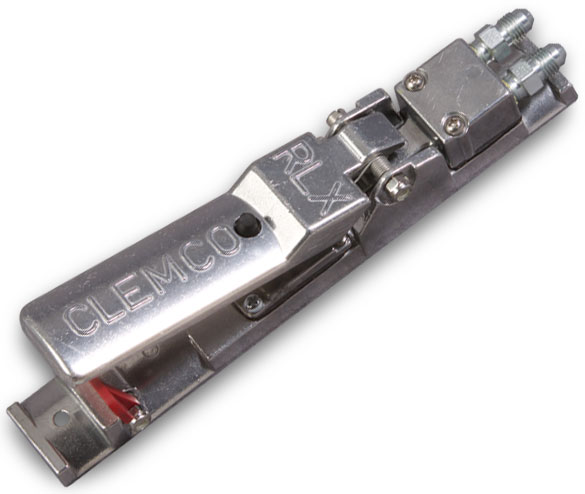

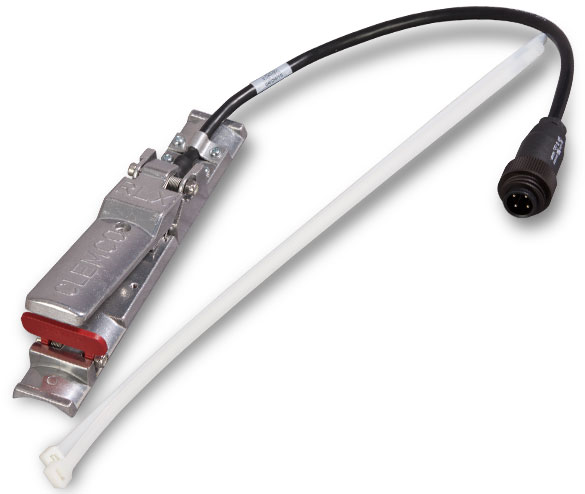

RLX Remote Control Systems: Pneumatic or Electric

Clemco RLX Remote Control Systems allow operators to start and stop blasting with fingertip controls located just before the blast nozzle. These fail-to-safe systems stop blasting if an operator drops or losses control of the remote control handle. OSHA regulations require that all abrasive blast machines be equipped with remote controls, and Clemco offers pneumatic and electric options.

- Pneumatic – Use with up to 100 ft of blast hose.

- Electric – Use with more than 100 ft of blast hose or when blasting in freezing temperatures. RLX Electric Remote Controls can operate efficiently with up to 500 ft of control cord. However, for distances greater than 300 ft, specialized control cord is required.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.