Product Reference Charts

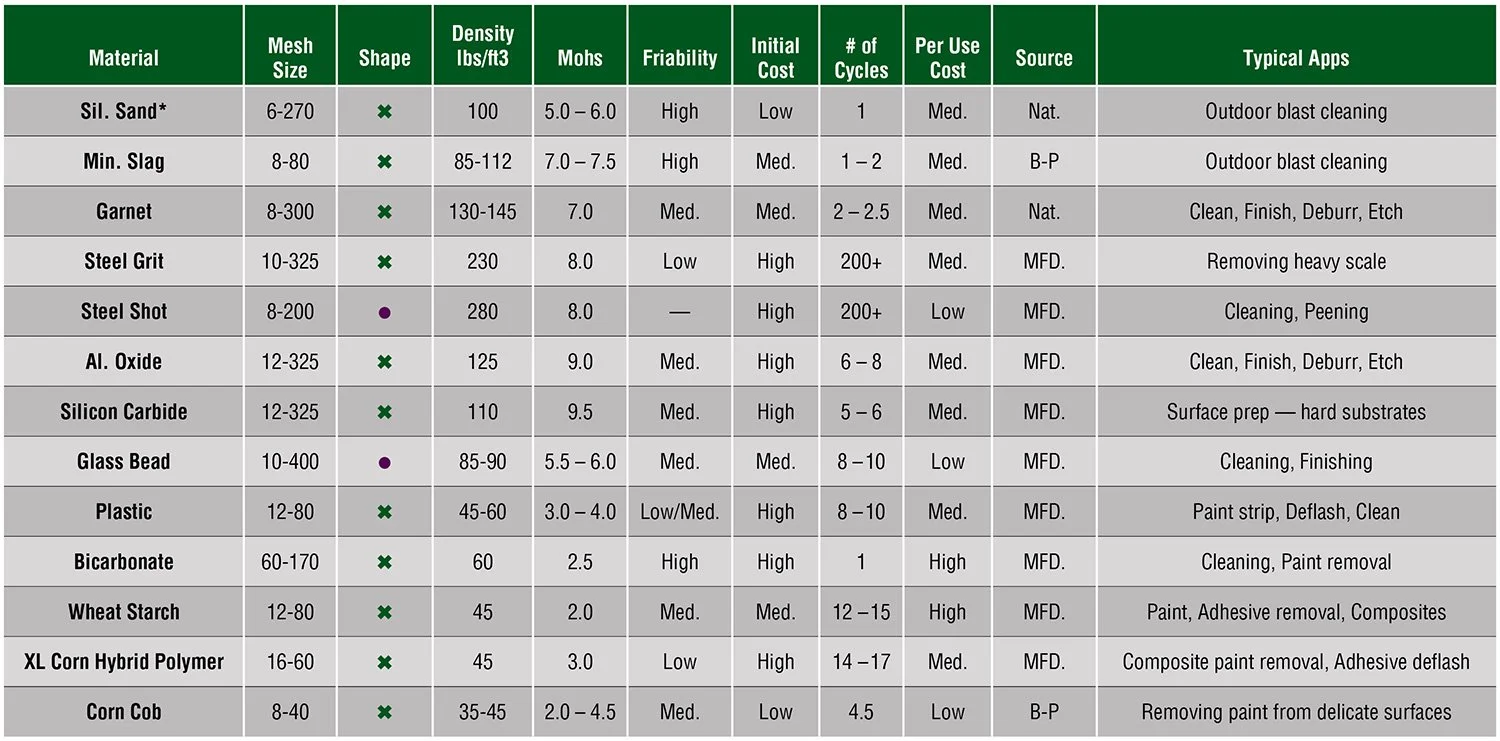

Blast Media Characteristics Comparison

X = Angular; • = Spherical | Nat. = Natural; B-P = By-Product; MFD. = Manufactured

* Consult OSHA regulations before using silica sand as a blast abrasive.

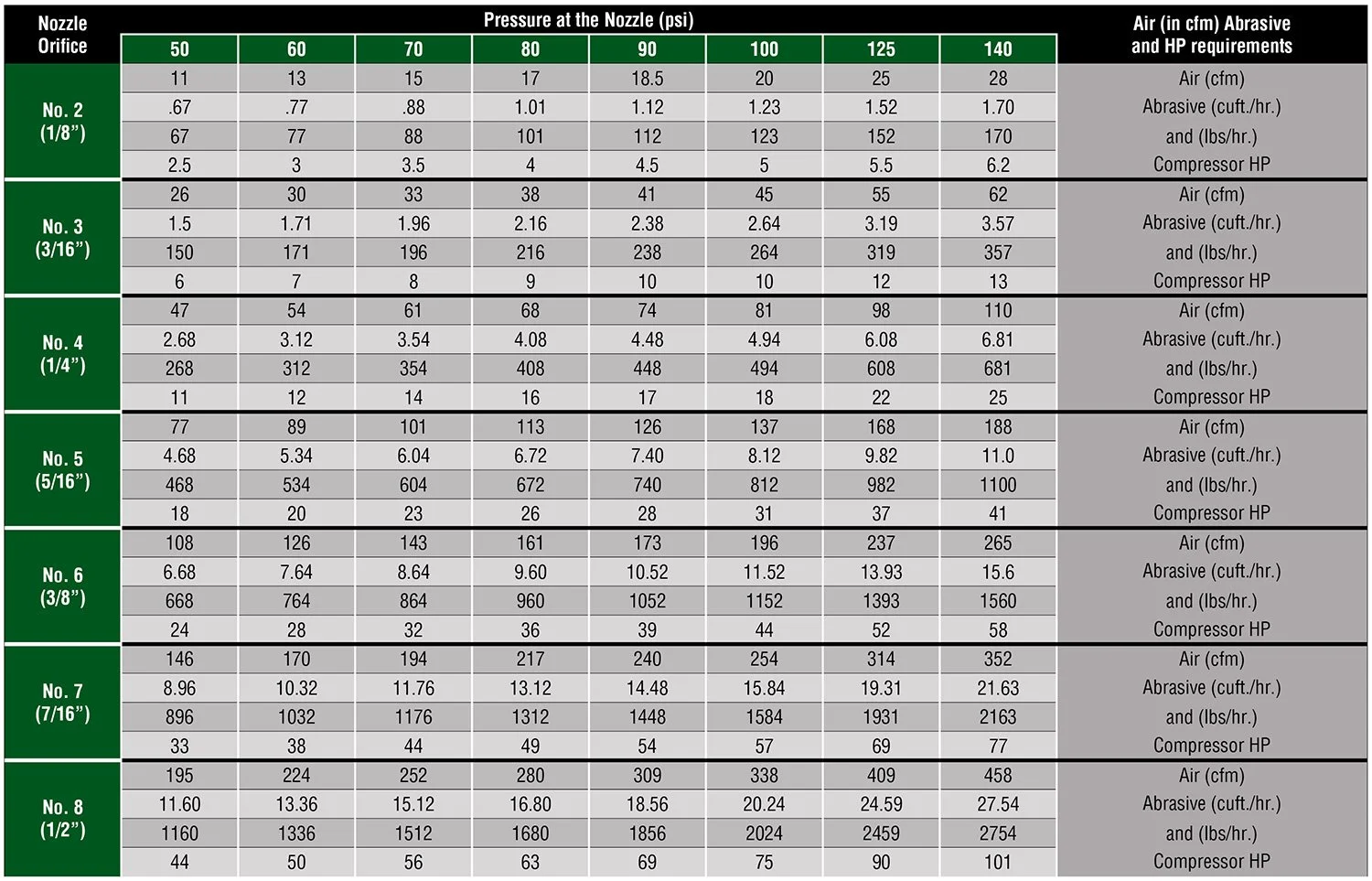

Blast System Air Volume Estimates

Compressed-Air & Abrasive Consumption

*Consumption rates are based on abrasives that weigh 100 lbs per cubic foot.

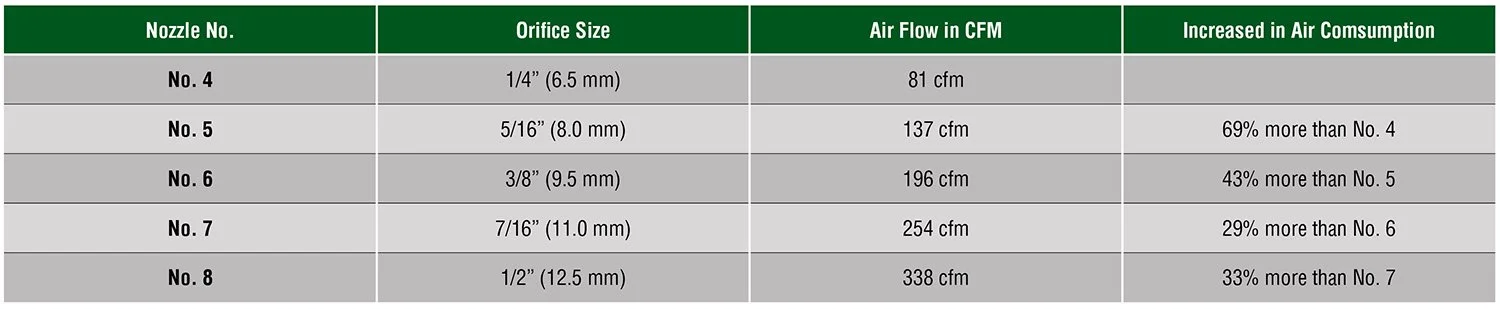

Effects of Nozzle Wear on Air Consumption

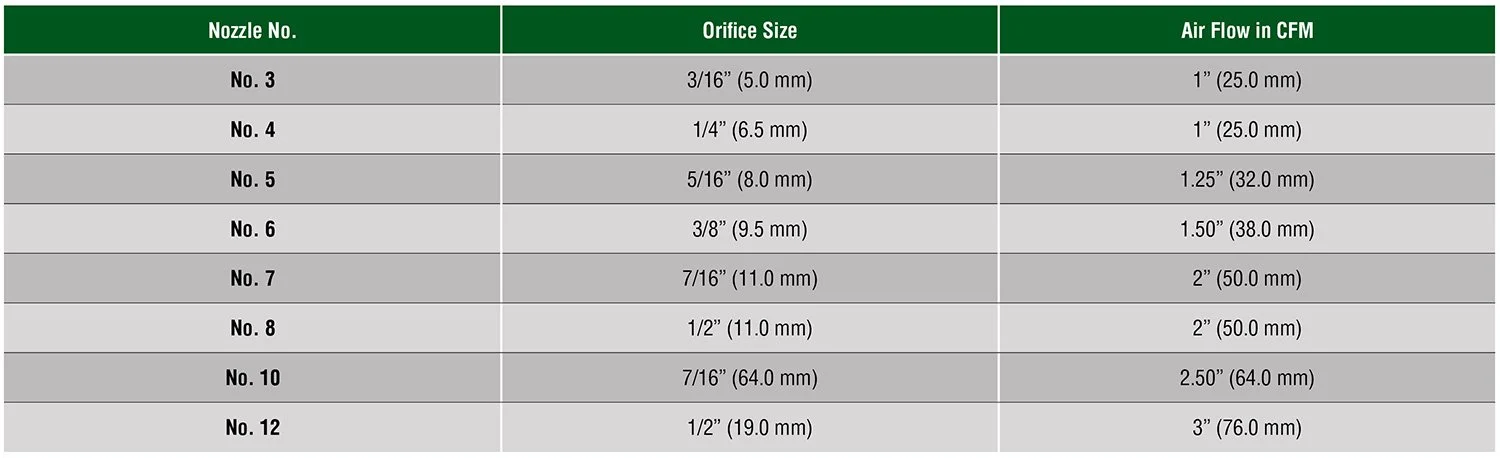

Minimum Compressor Air Line Diameter

Proven Performance. Rugged Reliability.

Generations of Excellence Transforming Our World, Worldwide since 1949

•

Generations of Excellence Transforming Our World, Worldwide since 1949

•

Generations of Excellence Transforming Our World, Worldwide since 1949

•

Generations of Excellence Transforming Our World, Worldwide since 1949 • Generations of Excellence Transforming Our World, Worldwide since 1949 • Generations of Excellence Transforming Our World, Worldwide since 1949 •