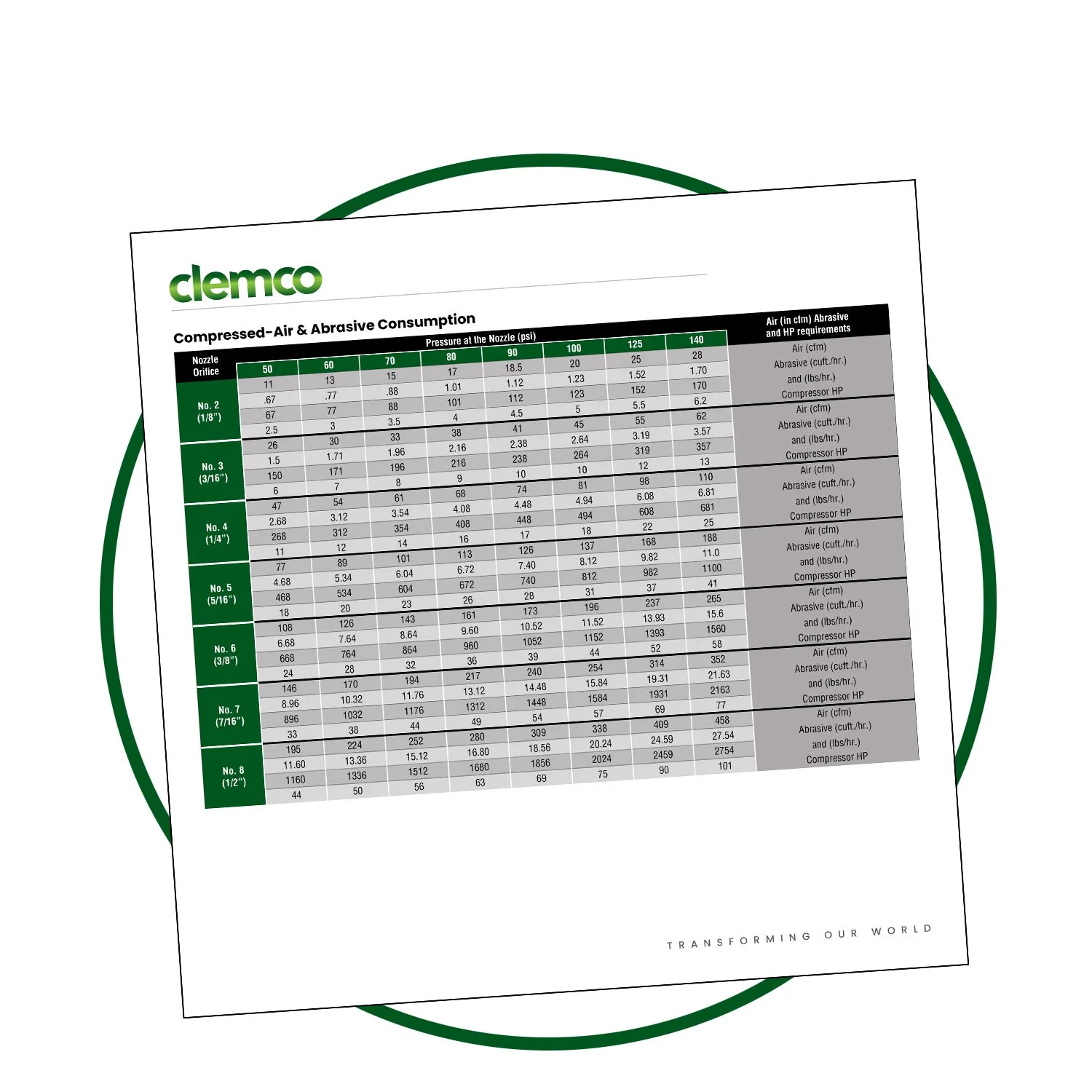

Manuals | Catalog | Videos | Charts | Blast Off

Need Some Help?

To provide you the best possible service, Clemco offers a global network of Intercompanies and authorized distributors. To get started, please use our form to send your email directly to our headquarters in Washington, Missouri.

customerservice@clemcoindustries.com

(636) 239-4300

One Cablecar Drive

Washington MO 63090

Proven Performance. Rugged Reliability.

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 •