Dry-Blast, Wetblast, Lightweight-Media, Economy, and Tumble

Cabinets—For Your Unique Blasting Requirements

Whether you use media blast cabinets to surface prep automotive springs and general fasteners, clean molds, finishing 3D-printed parts, or strip coatings off aerospace landing gear for inspection, abrasive blasting is a critical component of your manufacturing process—that needs to keep pace with the rest of your production line. You can’t have inferior-performing abrasive media cabinets that result in inconsistent blasting quality, difficult operation, or unscheduled maintenance. You need consistent, repeatable results; reliable throughput; and a quick, verifiable return on your investment. You need a Clemco industrial abrasive blast cabinet—cabinets that deliver what you need and what your customers require.

Dry-Blast Abrasive Cabinets – Pulsar Plus

You manage a highly efficient cell production line. You need manual blast cabinets that can keep up with your output demands and with your production team. Additionally, your blast cabinets often run multiple shifts and are manned by different operators, so your hand cabinets must be reliable enough for continuous operation and adaptable enough to keep blast operators of different heights and experience levels comfortable and productive. Clemco’s line of Pulsar Plus Blast Cabinets have compact footprints, are equipped with 17 ergonomic and productivity-enhancing standard features, and are simple to operate and maintain. They keep your operators and production line working at maximum productivity.

- Six models for accommodating different part size and space requirements.

- Suction and pressure systems to match your production needs.

Dry-Blast Abrasive Cabinets – BNP

When you need dry-blast abrasive cabinets that can handle the various-sized parts your team blasts and that also are easy to maintain and operate, you need a Clemco BNP Blast Cabinet. These cabinets provide you with detached reclaimers and dust collectors, so they can easily be configured for different floor plans and have straightforward access for maintenance, adjusting settings, and customization.

- Thirteen models ranging from small to standard to double-wide to accommodate various size parts.

- Suction or pressure systems offered depending on your production needs.

Wetblast Abrasive Cabinets

Traditional dry blasting isn’t getting you the results you need. Maybe your parts are coated with grease, or you need an extremely smooth finish or a contaminant-free finish. When you have these or other highly specialized application requirements, a Clemco Wetblast Abrasive Blast Cabinet may be the solution.

- Two models: Choose the one that accommodates your part sizes.

- Small footprints that fit into in various-sized production facilities.

Lightweight-Media Blast Cabinets

Your need manual abrasive blast cabinets that remove coatings—without damaging the surface being blasted. Perhaps this is required for inspection of fatigue points on high stress areas of aerospace components, or for cleaning automotive engine and body parts. For these and other blasting applications on delicate parts, Clemco’s line of Aerolyte Abrasive Blast Cabinets are specifically designed to blast with lightweight, nonaggressive media.

- Four Plastic-Media Pressure Blast Cabinets for dry stripping with recyclable plastic media.

- Two Bicarbonator Pressure Blast Cabinets for cleaning or paint stripping with sodium bicarbonate.

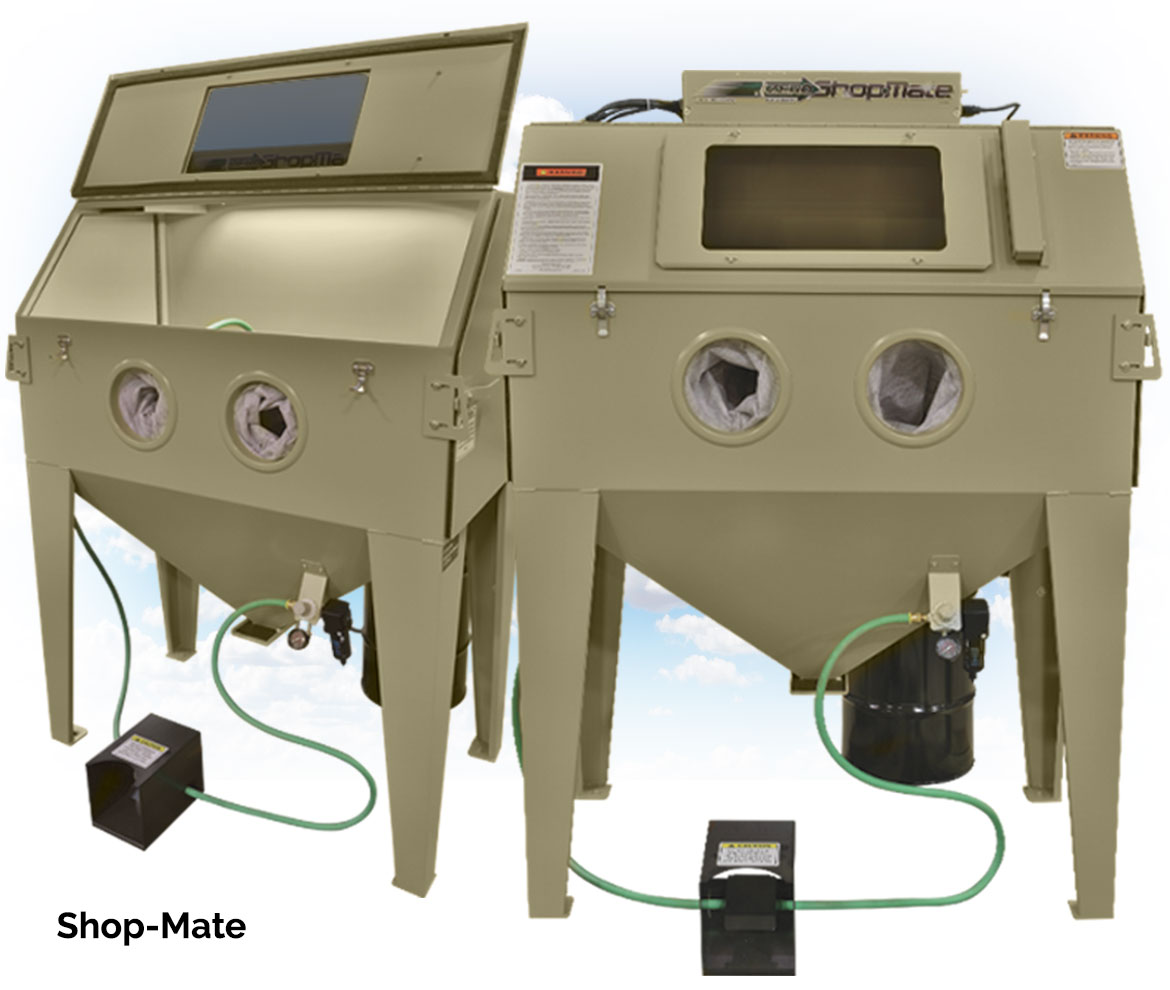

Economy Dry-Blast Cabinet

If you abrasive blast a few hours a week, are new to abrasive blasting or have a tight budget, Clemco’s ShopMate Economy Abrasive Blast Cabinet delivers consistent, high-quality results.

- One model: Suction system.

- Light-use cabinet for auto shops, art studios, maintenance departments, machine shops, and other industrial applications.

Tumble Abrasive Blast Cabinet

Manually blasting batches of small parts is time-consuming, and operators are prone to inconsistent performance as they fatigue. Ensure consistent blast coverage of parts and reallocate operators’ labor to other duties by blasting a batch of parts at one time with Clemco’s Tumble Abrasive Blast Cabinets. These compact footprint, set-it-and-forget-it cabinets require little to no operator supervision while blasting.

- Light Duty: Three Tumble-Basket Cabinets – If you abrasive blast a few hours a week, for full shifts, or are new to tumble abrasive blasting. Two suction models that can process up to 25 lbs of parts, and a third suction model that can process up to 35 lbs.

- High Production: Three Tumble-Barrel Cabinets – Perfect for automotive rebuilders and small parts manufacturers. Three suction models. The largest model can process up to 300 lbs of parts.

- Super Duty: Three Tumble-Belt Cabinets – All three models available in suction or pressure systems. The largest model can process up to 800 lbs of parts.

For More Information

If you’re eager to learn more, simply complete the brief form below and our team of knowledgeable experts will be in touch with you. We sincerely appreciate your interest and look forward to connecting with you soon.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.