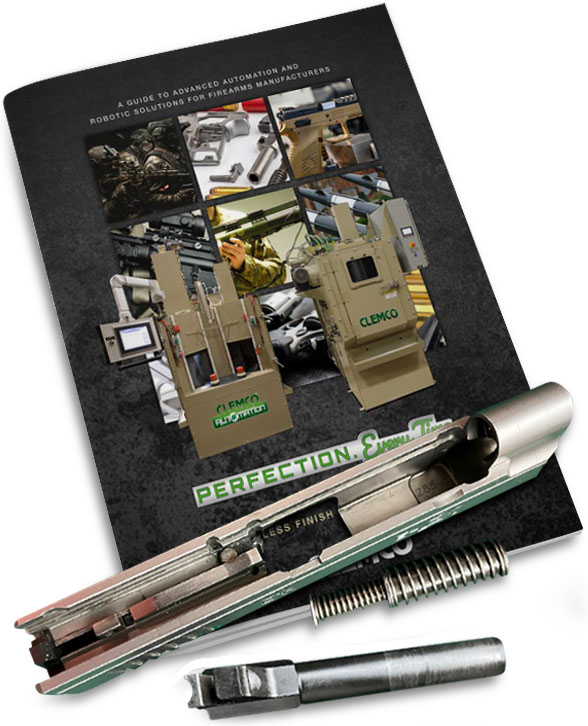

Get Your FREE Guide to Boost Your Productivity

Are you ready to take your business to the next level of production and excellence? Download our FREE guide to learn how Clemco can help you get there! Inside, you’ll find details on how we can help you reach new heights in:

- An automated abrasive blasting solution that allows for a perfect surface finish every time.

- A strong return on investment through lower overhead and a more streamlined production.

- An abrasive blasting solution that, overall, is safer for parts and people.

- Plus more!

Ready to talk? We don’t put pressure on our customers, Instead, we take the time to truly listen to your needs and provide you with reliable and effective solutions if we feel we are a good fit.