BLAST EQUIPMENT INVESTMENT:

Unlocking the Secrets to a Successful Blast Equipment Investment

In my numerous years in this business, I’ve been fortunate to work with many skillful and intelligent engineers and plant managers, well-schooled in their lines of work and areas of expertise. They bring me projects that challenge me, …

Unlocking the Secrets to a Successful Blast Equipment Investment: A Guide to Planning, Communication, and Documentation

In my numerous years in this business, I’ve been fortunate to work with many skillful and intelligent engineers and plant managers, well-schooled in their lines of work and areas of expertise. They bring me projects that challenge me, which makes my job interesting, as I enjoy solving problems. While my involvement is always at the front-end of the project, my objective is a satisfied customer for the long-term. Solving the problem in the lab is only part of the successful purchase equation.

Frequently, customers are bringing a process in-house that they had been jobbing out and, as a result, are now investing in new equipment. Much of the time, these customers don’t have a complete grasp of the impact of their decision. In the ideal situation, we process their samples and work together to achieve often lofty objectives and expectations.

The early discussions entail general process requirements and whether an automated system is needed. Usually, there are two primary drivers leading to the decision to choose automation: high production volume and/or the need for precision processing and exact repeatability. For some jobs, it is essential to produce identical parts each time, and that requires removing the human element.

Sometimes, without the customer realizing it, we’ve worked through a long list of requirements, which, when carefully considered as a whole, form the basis for the design of the machine that will meet their production goals and budget constraints.

Whether the process is shot peening or blast cleaning or finishing, the preparation drill remains the same. Fully understanding the process (that’s where I come in) and considering the gamut of work-flow issues (considerations and limitations that exist at the customer’s facility) are essential to a successful outcome.

To help my customers, I’ve come up with two “top ten” lists of planning considerations.

The first one involves what I call the environmental considerations of their business and workplace, which include:

- Production objectives-it’s important to consider the number of parts that need to be completed in each period. How the production rate can be met must include allowances for the loading and unloading of parts by the operator. It’s important to set reasonable and achievable goals.

- Available air supply and electrical service-all blast processes require dry air of sufficient volume and pressure for the number and size of nozzles or orifices specified. A baseline for the air supply should be established. It’s important to understand that the volume necessary for operation must take into consideration wear of nozzles, which as they wear consume more air. Sufficient electrical amperage is needed to power blowers and other equipment. How much is currently available, and will additional amperage be needed?

- Available space in and around the process area, the height, width, and depth needed for the equipment plus ducting, space available for parts staging, and for access to the equipment for service and maintenance. Are there ceiling height or other limitations?

- If the equipment will require a pit, are there water-table issues to consider?

- Condition of the parts prior to blasting-are they greasy, or hot, or cold, or do they have flashing that might impact the blast process equipment? Hot parts can melt plastic media or be too hot for the operator to handle. As parts cool, condensation can cause moisture issues. Moisture is the enemy of blasting.

- Pre-process treatment before blasting/peening-how will the degreasing, cooling, warming, or other prep work take place-where and by whom and how will the part be brought to the blast cabinet or room?

- Post-process part handling-where will the parts go next and how will they get there? Will the same operator who services the blast cabinet be responsible for parts’ transport? How will this affect production rate?

- The production line-how will the blast cabinet fit into the existing workflow. Is there sufficient space for one or more operators to work in the area? Will their movements be efficient? Wasted movement costs money in indirect labor.

- Skill level of the operator(s)-will they be capable of working with PLCs (programmable-logic controllers) or should the equipment be equipped with manual pushbuttons?

- Budget as it relates to current and future production requirements-it’s wise to try to anticipate changes to production requirements in the near and medium term. A rule of thumb might be to build into the project an increase of 10% to 20%. Sometimes, that is not possible, of course. But the issue should be carefully considered.

The second list involves the process, the technical considerations surrounding the blasting or shot peening, including:

- Recognizing the need to learn about shot peening and understanding the meaning of intensity, saturation, and coverage.

- Reading and understanding the applicable specification as well as the requirements shown “on the print” for the part to be processed. For shot peening, there are specific documents that govern all aspects of processing a particular part.

- Carefully reviewing the geometry of the part that will dictate how the blasting or peening will be done. The shape and size and configuration of the parts impact how they are processed. This is one of the reasons that sample processing in my lab is so important. Each part has specific process differences. Some parts have small holes that require pressure blasting with a side-angle lance.

- Designing and fabricating the part holding fixtures for easy part placement and removal—I the fixturing can impact production rate.

- Is masking necessary? Depending upon the desired blasting or peening coverage, designing, and fabricating appropriate masking is critical to ensure that the integrity of the part is maintained and covered as necessary and the area to be blasted is properly exposed.

- Selecting the type and size of the blast media. Here again, sample processing is critical to making the proper choice. Lab tests and understanding the environmental considerations that impact media selection would be done during sample processing.

- Is media classification required? In shot peening, keeping a good working mix of media requires classification equipment that will dispose of over-sized or under-sized particles and produce a mix that will ensure process consistency. Separation equipment can also discard unwanted out-of-round or broken media.

- Controlling the process and ensuring repeatability—will the process require computer controls to meet the relevant specifications?

- Achieving desired peening intensity—deciding whether suction or pressure blasting will produce good parts—here again, careful testing and sample processing will dictate how a part needs to be processed.

- Establishing required recordkeeping procedures. Attention to detail is critical in shot peening operations. Specifications frequently dictate the scope and methods to be put into place to satisfy the end user of the parts, which may go into aircraft engines, automobiles, spacecraft, or other equipment that depend on proper procedure to ensure public safety.

In summary, if we’ve learned anything over the years, it is that the human animal detests filling out forms. Unfortunately, this distaste for procedure represents perhaps the greatest obstacle to ensuring a successful outcome.

The two lists we’ve offered are intended to encourage the free flow of information between the customer and the equipment supplier. Each bit of information represents a springboard for development of a comprehensive plan to design and deliver equipment that will achieve the customer’s objectives and expectations. Communication is key. Documentation is extremely useful both for the customer and the supplier as, on occasion, personnel changes occur during the procurement process. A seamless transition is possible only when everything is spelled out and documented as the project moves forward. Documentation is useful for design reference and for being the brains that recollect an agreement to certain stipulations. It provides insurance and peace of mind…a small effort for a large pay out. Certainly, every investment in new equipment demands a measurable payback. Careful planning, good communication, and diligent documentation are keys to a successful outcome.

MAKE THE RIGHT CHOICE:

Choose the Right Blast Cabinet Model for Maximum Performance and Productivity

Choosing a blast cabinet model is a bit more complicated than it may appear on the surface (no pun intended). An easy way to ensure the highest performance and productivity from a blast system is to make sure the system components are sized correctly. …

Choose the Right Blast Cabinet Model for Maximum Performance and Productivity

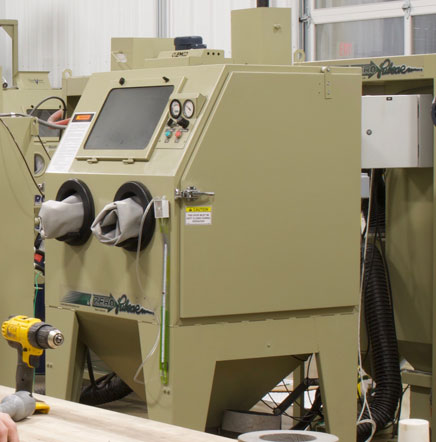

Choosing a blast cabinet model is a bit more complicated than it may appear on the surface (no pun intended). An easy way to ensure the highest performance and productivity from a blast system is to make sure the system components are sized correctly.

Beyond considering the size of the parts to be blasted, it is critical to consider the media to be used and the size of the nozzle.

Media varies in friability (how quickly it breaks down) and therefore the size of the reclaimer needed for good visibility and efficient operation is important. For media that breaks down rapidly, causing heavy dust loading, a cartridge collector is recommended.

For lightweight or extremely fine media (200 mesh or finer), we recommend an adjustable vortex cylinder and removal of the media knockdown baffle. Removing the baffle minimizes the carryover of usable media to the dust collector. When plastic media or other non-aggressive media are to be used, always order an Aerolyte model, engineered for those applications.

For heavier media such as steel grit (max 050) or shot (max S 170), we recommend a 900 cfm or larger reclaimer on the BNP65 or 220. And a 1200 cfm or larger reclaimer is needed on BNP600, 720 and double cabinet models. Hose end adaptors must be sized for heavier media and rubber curtains are a good idea. Standard BNP pressure cabinet models (and Pulsar kits) are available for metallic media. See BNP cabinet pages in the price list.

When a nozzle larger than the standard size is used, the recovery system should be of greater capacity to maintain visibility and to convey the additional media delivered by the nozzle.

For more information, read the owner’s manual. Our manuals offer a wealth of good operation, service, and troubleshooting advice. The more you know, the more comfortable you will be discussing your customers’ needs and you’ll ensure your customers get the equipment that best suits their operation. Product Operation Manuals

STATIC BUILDUP:

Controlling Static Buildup to Improve Efficiency and Safety in Abrasive Blasting Operations

Though more noticeable during the dryer winter months, static build up is always an issue for blasting operations, at any time of the year. A few simple steps taken to control static electricity will produce a safer, more comfortable, and, …

Controlling Static Buildup to Improve Efficiency and Safety in Abrasive Blasting Operations

Though more noticeable during the dryer winter months, static build up is always an issue for blasting operations, at any time of the year. A few simple steps taken to control static electricity will produce a safer, more comfortable, and, of particular importance, more efficient blast operation.

Most of us will admit that we read the owner’s manual that accompanies our new purchase only when we encounter a problem. So, worth noting here is the fact that every CLEMCO cabinet operation manual contains important information about the safe and efficient use of our equipment. Reading the manual and selecting the right media for your blast application are only the first steps to achieving an efficient operation.

Blasting, by definition, brings together elements that as a matter of course have materials flowing through pipes or hoses; the activity and conditions surrounding blasting generate static electricity. Dry air, essential to an efficient blasting operation, contributes to the buildup of static electricity. The movement of blast media particles through hoses to the nozzle/ gun, over the part being blasted, and in the recovery, hose generates static electricity. Cyclone-type separators and media classifiers, where media and dust swirl over large surface area, normally generate a static charge. This charge must be continuously dissipated to prevent an accumulation of an electrostatic charge that can result in a spark. If not dissipated, in a manual blast operation, the static charge is released when the operator comes in contact with the cabinet, usually around the armhole or wherever the operator leans against the cabinet.

To keep static electricity from building to a dangerous level, which may cause a fire or an explosion, the cabinet must be connected to an earth ground. With all the components interconnected, all are at the same electrical potential.

Take care to do the job properly when grounding equipment. Connecting to a metal-frame building, water pipe or electrical conduit on the wall does not control static, as an electrical neutral wire or third-wire ground may carry static current in certain locales. When grounding, clean and remove any paint and rust from the contact area for a good conductivity. It is prudent to consult the requirements of the National Electric Code and National Fire Protection Association Lightning Protection Code.

Static grounding cables must be low resistance at or below 5 ohms of ground. For permanent installations, check the ground with an ohmmeter at least once a year. For temporary or portable installations, check the static ground at start up and again each time the equipment is moved.

To avoid getting ‘zapped’, even with a well-grounded cabinet, keep the part being blasted in contact with the metal grate or attach a ground clamp to the part to dissipate the charge created by the blast media exiting the nozzle and going over the part.

And, not all rubber mats are created equal. If you stand on a rubber mat, make sure it is designed to dissipate static and is connected to earth ground. At the time of manufacture and assembly, all CLEMCO cabinets are fitted with air- and media-conveying hoses that contain a conductive material to reduce static; similarly flexible exhaust hose contains a spiral wire. The spiral wire serves two purposes. First, it keeps the hose from collapsing under vacuum, and second it helps dissipate static build-up in the hose when grounded at each end. The spiral wire is not a replacement for a ground wire to each component.

Sometimes, despite proper grounding throughout the blast equipment, a static charge can build due to the type and configuration of the part. And some parts, such as semi-conductors can be damaged by static electricity. Though overlooked by many people, clothing and the type of shoes worn by the operator can contribute to the problem. With sit-down style ergonomic cabinets, the operator may be isolated from the ground and therefore vulnerable to a static charge. Wearing conductive shoes and keeping a foot on the grounded cabinet will prevent the operator from becoming charged. Avoiding all nylon clothing is also a good idea, as nylon is an insulator.

From an operational standpoint, when static electricity is left unchecked in a manual or automated system, the static can cause media flow and separation problems. Media will cling to the cabinet walls, will hang up in the recovery hoses, and even cling to itself resulting in media flow problems. With a static charge, media may cling to the part, and negatively affect the media cleaning process as fines and broken particles will cling to the larger reusable particles.

Grounding is the key to reducing the risk of static shock and avoiding efficiency-robbing static build up throughout the blast system. Taking these extra steps makes working at the blast cabinet more comfortable for the operator and ensures the cabinet system functions at its optimum level of performance.

SAMPLE PROCESSING:

How Sample Processing Can Help You Automate Your Blast Cleaning or Shot Peening System

Many customers ask what criteria I use to determine if an application could benefit from sample processing. Customers surprise me all the time with unique applications, but a few common characteristics usually indicate a need for sample processing. …

Discover How Sample Processing Can Help You Automate Your Blast Cleaning or Shot Peening System

Many blast equipment Distributors have a manual cabinet set up for basic sample processing. This first-line sample processing demonstrates that manual blasting can safely clean or finish a part.

For automation applications, most Distributors choose to send sample parts to the CLEMCO lab in Washington, Missouri, for evaluation and processing. CLEMCO’s sample processing technicians test blast or shot peen these representative parts, while modifying the variables. These variables include:

- Suction or Pressure Blasting

- Type, Number, and Size of Nozzles or Guns

- Position of Nozzles or Guns (distance, angle, spacing)

- Blast Pressure

- Dwell

- Nozzle Oscillation Speed

- Part Movement

- Media Composition and Size

CLEMCO’s technicians maintain painstaking records of each process run and mark each part. These parts are returned, along with the test results, so the customer can make an informed decision.

The goal of sample processing–design an automated system to get the desired finish, consistently, and economically.

The simplest automation applications take parts of relatively consistent size, shape, and condition, and apply a predetermined process to produce nearly identical results over a long production run. With the help of quick-change fixtures and programmable controllers, however, CLEMCO can build systems to handle an assortment of parts over short or long productions runs.

If you have one or more of the following, issues an automated blast cleaning solution may be the solution:

- Two or more employees spend more than half of each day cleaning parts. (Automation, can quickly return its investment by saving labor, speeding production, and reducing rework.)

- Surface preparation – chemical processes, hand sanding, or manual blasting – has become a bottleneck in your production line.

- Your current process takes too long. Or drying the parts after chemical processing takes too long.

- Your surface preparation involves toxic chemicals. (When your factor in the health and safety issues, environmental compliance requirements, and disposal costs for chemicals, an automated blast system can usually pay for itself in less than a year).

- Your current process produces inconsistent results or causes excessive rework. This is especially true for shot peening, where verifiable and repeatable results are critical to part performance.

- In the past year, you have worn out a manual blast cabinet or have spent more than half the cost of a new manual cabinet keeping your old one running.

- In the past year, you have worn out one or more employees who prep parts.

- You, your mother, your brother, and your children have grown tired of working night and weekends hand prep ping parts for the next day’s production runs.

Ask your Distributor to help you evaluate your current process. He or she can arrange sample processing in the CLEMCO lab and provide a firm quotation on the equipment you need.

INDEXING CABINETS:

Manufacturer Achieves 3X Production Rate with Automated Blasting System

A manufacturer of stainless steel laparoscopic surgical tools wanted to improve efficiencies in their finishing operation. Their instruments were machined and came from the fabrication shop with burrs, small defects, surface oxide, and slight discoloration. …

Manufacturer Achieves 3x Production Rate with Automated Blasting Solution for Surgical Tools

Problem: A manufacturer of stainless steel laparoscopic surgical tools wanted to improve efficiencies in their finishing operation. Their instruments were machined and came from the fabrication shop with burrs, small defects, surface oxide, and slight discoloration. With a production volume about 4,000 pieces per week, they needed to process at a rate of one finished part every 10 seconds.

Their finishing objectives included deburring and cleaning to remove oxidation and other contamination from the parts. Their manual process included sanding and wire brushing. A routine step also involved visually inspecting each finished part with a magnifying glass, a painstaking process.

Attention to detail and a fine finish were required to meet the demands of their medical community customer base, not to mention outshining their competition.

Solution: We offered to run parts for them to demonstrate how blasting could contribute to improving their operation and the customer took the distributor up on his offer. The surgical instruments were processed with No. 10 glass bead in suction-style (venturi-style) blast cabinet.

To the uninitiated, blasting is like magic. The customer purchased a manual cabinet. And not only were they able to achieve their production rate, but also, they saw an improvement in the quality of their parts. Glass bead blasting quickly and easily removed the burrs and oxidation and produced a matte finish, which was an unexpected but pleasant surprise. As you know, surprises in a manufacturing environment usually are not desirable! To the manufacturer’s delight, their customers raved about the matte-finish it served to eliminate the reflective glare on the instrument from the operating room’s high-intensity lighting, an obstacle they had lived with for years. Removing the shine from the instruments’ surface instruments increased surgical productivity.

With this value-added feature, tool production demand increased, and the manufacturer turned to Clemco once again for advice. This time, with challenging new requirements. They wanted to double their production to two parts every ten seconds.

Automating the blasting process involves careful assessment of the parts to be finished, the finishing objectives, any material properties or characteristics of the part that would dictate special handling, as well as consideration for the space and environment where the equipment will be used in the customer’s facility.

In this instance, the customer needed a machine that would speed the process so that production could be ramped up to meet greater demand. They wanted finished parts with a single process and an easy operational learning curve for the workers. They needed a reliable, easy-to-maintain machine that would run 24hr. if need be.

The parts had to be handled individually and lent themselves to an indexing turntable machine, in which parts are loaded individually onto a fixture and blasted one or two satellite stations at a time. In this application, the customer loaded three parts on one fixture, indexed to send the parts inside the cabinet for blasting, while they removed and reloaded more parts.

The finishing specification called for uniform coverage over 360 degrees around the part. In some medical applications, such as implants, specific roughness average (Ra) finishes are required. In this application, however, the goal was a visually acceptable part. The machine was fitted with eight blast guns and the same No.10 glass bead that was used in their manual blast operation was also used here.

To achieve the customer’s finishing goals, we created special fixtures designed to hold three parts per fixture. By loading three parts on each fixture, three parts could be completed every ten seconds and the finishing production rate tripled the original manual-process rate, giving the customer room to grow into the machine with increasing demand. For the time being, the additional finishing capacity allowed them to process several different size tools with a simple change-out in fixtures. The automated process assures repeatability, which contributed to greater time and cost savings by reducing the visual inspection rate and virtually all part reworks.

The challenge had been to design a machine and process that would offer a simple, elegant solution at a price that was within the customer’s budget. Solving customer problems are never a slam-dunk. In this project, with a combination of luck, and of course skill and expertise (I), the customer was thrilled with their investment in a simple automated process, with achieving triple their production rate, and with the assurance that they would not very soon outgrow the machine. Their business continues to grow, and, in their eyes, we shined.

SHOT PEENING:

10 Ways Shot Peening Delivers Quality for Today’s Manufacturers

Manufacturers in the aerospace, automotive, infrastructure and other critical industries rely heavily on automated shot peening to boost the performance and service life of their high-strength metallic products and parts. This is because…

Automated Shot Peening Delivers Consistent Benefits, Quality and Value for Today’s Manufacturers

Manufacturers in the aerospace, automotive, infrastructure and other critical industries rely heavily on automated shot peening to boost the performance and service life of their high-strength metallic products and parts. This is because important metal parts that are subject to frequent forms of stress may fail prematurely through a fracture that begins at the surface, leading to potentially disastrous results.

Controlled and automated shot peening improves the permissible stress levels for these parts and materials while also providing the essential documentation manufacturers desire for achieving their unique quality objectives. While the shot peening needs of different manufacturers can vary widely, those with certain common challenges can benefit from shot peening in numerous ways.

Increase Fatigue Life

Fatigue failure is the wearing out of metal due to repetitive and cyclical stress loading, which causes bending and twisting. Shot peening improves fatigue life on parts exposed to repeated stresses, but it must be controlled and repeatable and therefore performed in an automated manner. Automated shot peening is very effective for increasing fatigue life in aircraft landing gear, helicopter blades, leaf and coil springs, gear teeth, drive shafts, torsion bars, axles, chilling equipment, rotors, compressors, turbine blades, fuel injector parts, cam shafts, connecting rods and steering parts.

Reduce Stress Corrosion Cracking

Residual stress leaves metals more susceptible to corrosion, especially in high-strength materials. Stress failures result from the complex interaction of corrosives on sustained tensile stress in a metal surface. By applying a compressive stress layer to the surface metal through shot peening, its susceptibility is reduced. This application is effective with aircraft landing gear and stainless steel hydraulic tubing.

Prepare Parts for Plating

Chrome plating can have a detrimental effect on the fatigue life of metal parts. Fine cracks commonly develop in metal plating. Shot peening parts prior to plating strengthens the part and enables it to resist the transfer of cracks from the plating through the base metal. This is an effective application for landing gear cylinders and other metal parts to be plated.

Straighten Parts Deformed During Manufacturing

Parts can be straightened by selective peening along a critical area. The radial stretching and plastic flow effects of an opposing surface caused by shot peening can straighten parts to a certain degree. This can help with out-of-round piston rings, bulkheads, large structural shapes deformed during machining and parts deformed during heat treatment.

Reduce Tensile Stress After Grinding

The shot peening process converts residual stress from tension to compression in many parts. The tensile layer where failure occurs is converted to a uniform comprehensive layer, thereby increasing fatigue strength and lengthening service life. This is an effective application for high strength steel parts.

Test Bonding of Electroplated Surfaces

Poorly bonded surfaces will blister when shot peened, whereas a lack of blister indicates good adhesion. Shot peening can also expose imperfections and quality problems in electroplated surfaces. Best uses for this application are in detecting decarbonized (softer) surface areas on metal parts and in inspecting plated engine parts.

Reduce Casting Porosity

Shot peening parts with a carefully chosen media size can pack and compress surface grain, closing the pores through which hydraulic leakage can occur. This is an effective treatment for aluminum die-cast parts, transmission housings and gearboxes.

Alter Dimensions of Parts

During the design phase of product development, shot peening can be incorporated into the manufacturing process to slightly enlarge or reduce the part size as needed. During rebuilds, shot peening can be used to alter the dimension of parts negatively affected by wear. This process is effective for increasing the diameter of a shaft or decreasing the diameter of a hole.

Improve Oil Retention and Lubricity

Shot peening alters the surface of a part to reduce friction and improve oil retention, thereby improving lubricity of some bearing surfaces, engine pistons and cylinder walls.

Reduce Notch Sensitivity in High-Strength Steel

The stronger the steel, the more susceptible it becomes to failure from notching or fatigue cracking. Shot peening improves the life cycle of steel and reduces fatigue cracking. It is commonly used in many applications to treat steel strengths greater than 200,000 psi, particularly in landing gear and springs.

Deliver Value To Customers

The peening process, when properly controlled, delivers the same benefit to each part treated. Because so many variables can affect shot peening results, many manufacturers set their own process standards to ensure consistent quality whether shot peening is delivered in their plant or by their vendors. Maintaining and documenting the peening process provides essential evidence that the manufacturer is committed to quality and to providing value for their customer.

Clemco offers world class engineered and automated solutions that help today’s manufacturers optimize their entire shot peening process and achieve the value-added results they seek.

Copyright ©2023 • All Rights Reserved

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.