Personal Protective Equipment (PPE) Accessories

Increase Operator Comfort and Safety While Ensuring Regulatory Compliance and Abrasive Blasting Productivity

Abrasive blasting is dangerous, loud, and uncomfortable work. You want your operators safe from rebounding abrasive, comfortable in hot and cold temperatures, and in clear communication with their entire crew while they’re tackling their jobs. You know it’s the right thing to do because it keeps your crew focused, productive, and safe. That’s why you need Clemco PPE accessories and clothing. It helps your operators do their jobs safely and more effectively, which helps you run a productive and compliant operation:

- Heavy-Duty Blast Suits – For blasting with heavy, aggressive media.

- Lightweight Blast Suits – For hot weather, especially in peak blasting season.

- Leather Blast Gloves – Rugged and comfortable.

- Comfort Vest – Keeps operators’ upper bodies cool and warm.

- Apollo WiComm2 Bone-Conduction Radio Headset – Cutting-edge communication.

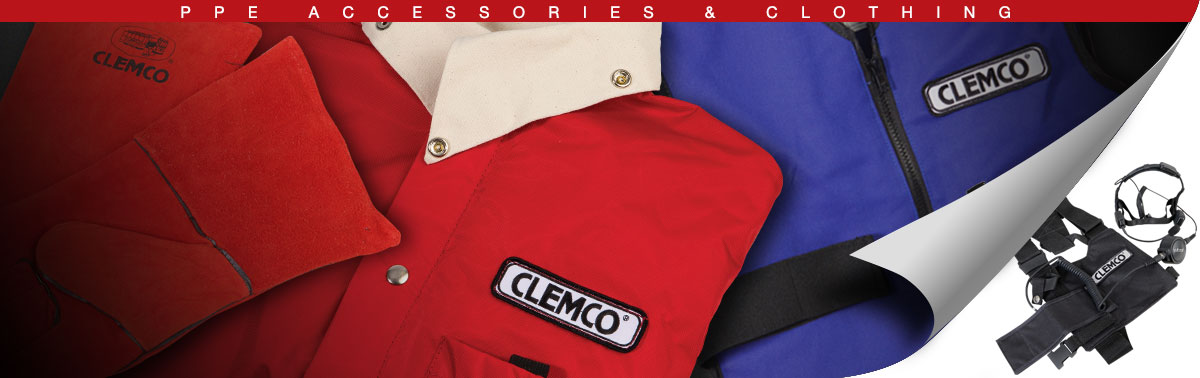

Heavy-Duty Blast Suits – For Blasting with Heavy, Aggressive Media

If your operators blast with heavy, aggressive media such as steel grit, you know that abrasive rebound can rapidly wear through less robust blast suits, which can be a serious injury hazard. Give your operators maximum protection from abrasive rebound without sacrificing comfort and mobility with Clemco Heavy-Duty Blast Suits:

- Durable – Rugged leather panels protect arms and legs, the two most-common abrasive-rebound wear points.

- Comfort and Mobility – Durable, heavy-cotton fabric backside allows suit to breathe, enhancing operator comfort, especially in hot weather. Cotton also allows for easier mobility.

- Secure – Straps at leg and hand cuffs for adjusting to fit keep abrasive and dust out of the suit.

- Selection – Available in Small to 3XL.

Lightweight Blast Suits – For Hot Weather, Especially in Peak Blasting Season

Your crew needs a blast suit that protects them from abrasive rebound—but it can sure get hot when they’re blasting in the summer, which increases their fatigue. Clemco Lightweight Blast Suits are constructed from lighter, cooler materials that still provide high-caliber protection from abrasive rebound:

- Durable and Comfortable – Nylon and cotton construction keeps operators cooler than heavier blast suits while still protecting them from abrasive rebound.

- Secure – Straps at leg and hand cuffs for adjusting to fit keep abrasive and dust out of the suit.

- Easy Upkeep – The suits’ nylon and cotton construction is suitable for machine washing.

- Selection – Available in Small to 4XL.

- Rental Yards – Popular item for rental yards to keep in stock.

Leather Blast Gloves – Rugged and Comfortable

Hands are vulnerable to abrasive rebound, and Clemco Leather Blast Gloves ensure that operators’ hands are protected and comfortable during abrasive blasting:

- Durable and Comfortable – Rugged leather construction is abrasive-resistant yet comfortable, and it ensures long service life.

- One–Size-Fits All – Leather naturally conforms to different hand sizes.

Comfort Vest – Keeps Operators’ Upper Bodies Cool and Warm

Abrasive blasting in extreme hot or cold temperatures not only is uncomfortable for operators, but accelerates fatigue, which eventually impacts productivity. Clemco’s Comfort Vest is a simple to use and set up solution for keeping operators cool and/or warm so that they stay comfortable and productive:

- Versatile – Lightweight, one-size-fits-most garment that can be worn underneath an operator’s blast suit or over a laborer’s work clothes.

- Effective – Directional air jets located on chest and back panels emit cool or warm air streams to the upper back and chest.

- For Cooling – Attach a Clem-Cool Air Conditioner or Cool Air Tube to the vest.

- For Warmth – Attach a Climate Control Tube to the vest.

- Safe – Constructed from nonflammable materials making it suitable for welding, foundries, and other work environments where sparks may occur.

- Easy Upkeep – Suitable for machine washing.

- Easy Set Up – Operates on 20 CFM of compressed air. Connect to an air supply separate from the breathing-air supply. After the vest is connected, it immediately provides continuous warm or cool air.

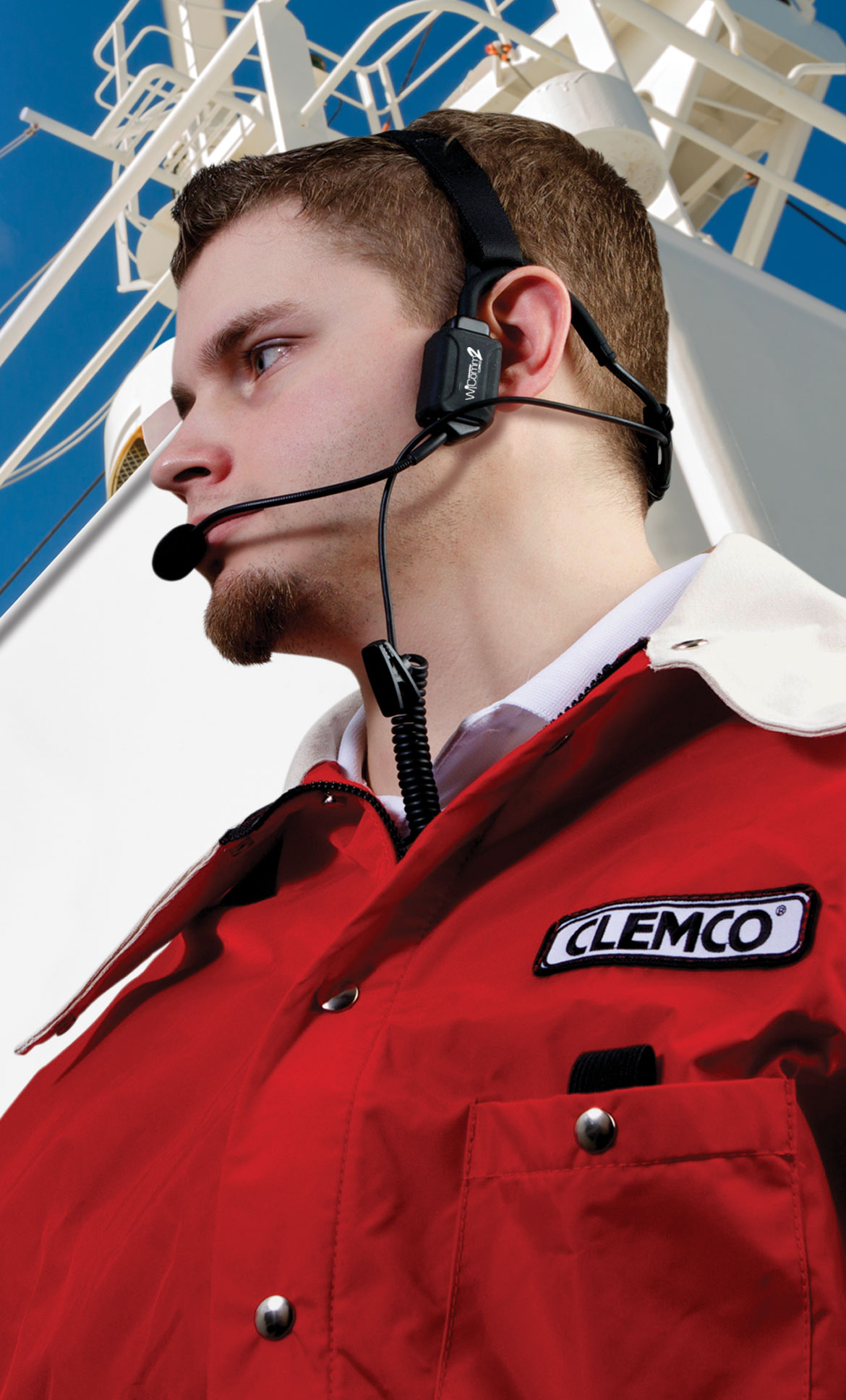

Apollo WiComm2 Bone-Conduction Radio Headset – Cutting-Edge Communication

Abrasive blasting is loud work, making communication among operators and supervisors difficult, especially if they are working at a distance from each other. But clear, immediate communication is critical for productivity and safety. Clemco’s Wicomm2 Bone-Conduction Radio Headset System facilitate clear, real-time communication, which helps coordinate the efforts of all crew members, cut down on mistakes and rework, and promote safety:

Clear, Immediate Communication – Productivity and Safety

- Ensures operators and supervisors have clear, real-time incoming communication.

- Noise-cancelling technology provides clearer outgoing communication.

- All crew members now can be confident that they have correct, up-to-the-minute information.

- Operators can more easily focus on their tasks at hand instead of being confused by unclear communication or concerned about not receiving important safety or operational information—improving productivity and safety.

Cutting-Edge Technology – Efficiency, Reliability, and Safety

- Bone-conduction radio headsets transmit incoming messages as mild vibrations through the jawbone—not through headsets that cover ears.

- Operators now can wear additional hearing protection in or over their ears, which decreases their exposure to noise above permissible exposure limits (PELs), enabling them to work longer shifts without risk of hearing impairment.

- These benefits promote safety and efficient communication far better than obsolete communication technologies.

- WiComm2 Radio Headsets have an IP67 Rating, which certifies that the headsets are protected against dust and water that can impact operational effectiveness and lead to system failures.

- For these reasons, police officers, firefighters, military personnel, and increasingly blast operators use bone-conduction radio headsets.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.