Abrasive Blast Rooms

Pre-Assembled Blast Rooms

-

Ready-to-Use Installation: Delivered fully assembled and designed for quick setup—just connect air and power to start blasting.

Compact Footprint: Measures 14’L x 7’W x 8’H, ideal for facilities with limited space.

Durable Construction: Built with heavy-duty 10-gauge galvanized steel panels for long-lasting performance.

Flexible Media Recovery Options: Choose between a pneumatic M-Section system for light media or a mechanical Flat-Trak system for heavier abrasives—both installable in pits or on existing foundations.

Integrated Support Systems: Includes 1,200 CFM cyclone or AWAC media cleaning, 4,000 CFM reverse-pulse dust collector, 6-cuft blast machine, PPE package, and more for a complete turnkey solution.

Pre-Designed Blast

Rooms

-

Variety of Sizes and Fast Lead Times: Offered in multiple width, height, and length combinations (up to 30 ft long) to accommodate diverse facility footprints with short delivery timelines.

Modular, Bolt-Together Construction: 10-gauge galvanized steel panels arrive as subassemblies for quick, easy on-site installation.

Customizable Media Recovery: Choose from a pneumatic M-Section system for lightweight media or a mechanical Sweep-In Hopper system for heavy/coarse abrasives—both installable in pits or aboveground.

Powerful Ventilation Options: Equipped with CDF-6 (6,600 CFM) or CDF-8 (8,800 CFM) reverse-pulse dust collectors, depending on room height, to ensure efficient dust control.

Complete System Package: Each setup includes a PPE kit, 6-cuft blast machine, and additional components for a turnkey blasting solution.

Engineered to Order Blast Rooms

-

Custom-Built for Specialized Needs: Designed specifically for your application, from aerospace to mining and industrial surface prep—delivered as durable, bolt-together 10ga galvanized steel subassemblies for efficient installation.

Customer Success Proven: Clemco has engineered tailored blast room solutions for complex tasks like stripping fighter jets, prepping mining truck frames, and cleaning large stainless-steel tanks.

Collaborative I2R™ Process: Clemco’s six-phase Ideation to Realization approach involves deep collaboration to diagnose and solve root issues, ensuring a solution that truly fits your operational challenges.

Flexible Recovery Systems: Choose from belt or screw conveyors, sweep-in hoppers, Flat-Trak, or M-Section systems to match your media type and blast room configuration.

Advanced Integration Capabilities: Supports manlifts, workcars, monorails, and automation—from robotic blasting to smart controls, HMI interfaces, and performance analytics.

Media Recovery

-

Maximize Media Reuse for Profitability: Reclaiming media reduces costs and increases blasting uptime—eliminating wasted time shoveling and media disposal.

Tailored for Your Media Type: Each system is designed to optimize recovery based on your specific abrasive, avoiding inefficiencies and premature equipment wear common in generic systems.

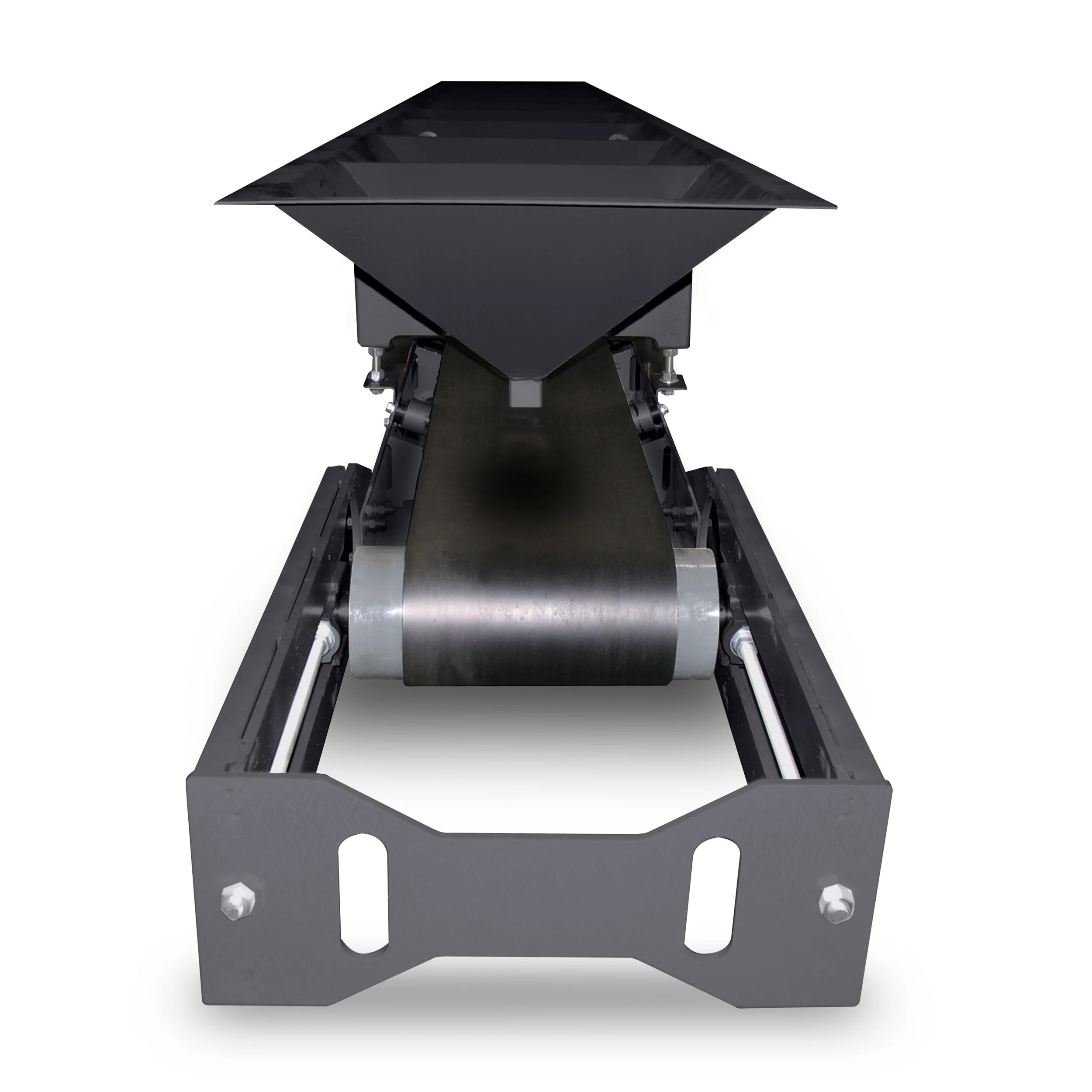

Five Specialized Recovery Solutions: Choose from Belt Conveyor, Screw Conveyor, Sweep-In Hopper, Flat-Trak®, and M-Section® systems—each engineered for different abrasive types and jobsite requirements.

Flexible Designs and Configurations: Whether mechanical or pneumatic, full-floor or partial-floor, Clemco systems can be adapted to fit your facility layout and process needs.

Built In-House for Quality Control: All recovery systems are fabricated and assembled at Clemco, ensuring high performance, reliability, and seamless integration with your blast operations.

-

Dust Collectors

-

CDF Dust Collectors – Designed for high-volume blast-room ventilation and large recovery systems, with modular airflow options from 4,000 to 88,000 CFM, automatic self-cleaning cartridges, easy 55-gallon drum dust disposal, and flexible indoor/outdoor installation.

RPH Dust Collectors – Suited for intermediate airflow needs (600–3,600 CFM), often paired with blast cabinets and recovery systems; feature reverse-pulse self-cleaning cartridges, 30- or 55-gallon waste drums, and simplified single-piece or bolt-together construction.

LPDC Dust Collectors – Compact and versatile with blower mounting options, side-loading filter access, and fan choices of 300/600/900 CFM; designed to fit through standard doors (78H x 29W x 29D) while enhancing dust containment and media recovery.

Efficiency and Maintenance – Both CDF and RPH units use reverse-pulse technology for consistent filter cleaning and long service life, while LPDC emphasizes easy access and portability in confined spaces.

Application Fit – Clemco’s three dust collector lines are engineered in-house to meet the productivity, safety, and environmental needs of abrasive blasting, from small cabinet operations to large blast room systems.

-

Product Brochure

Proven Performance. Rugged Reliability.

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 •