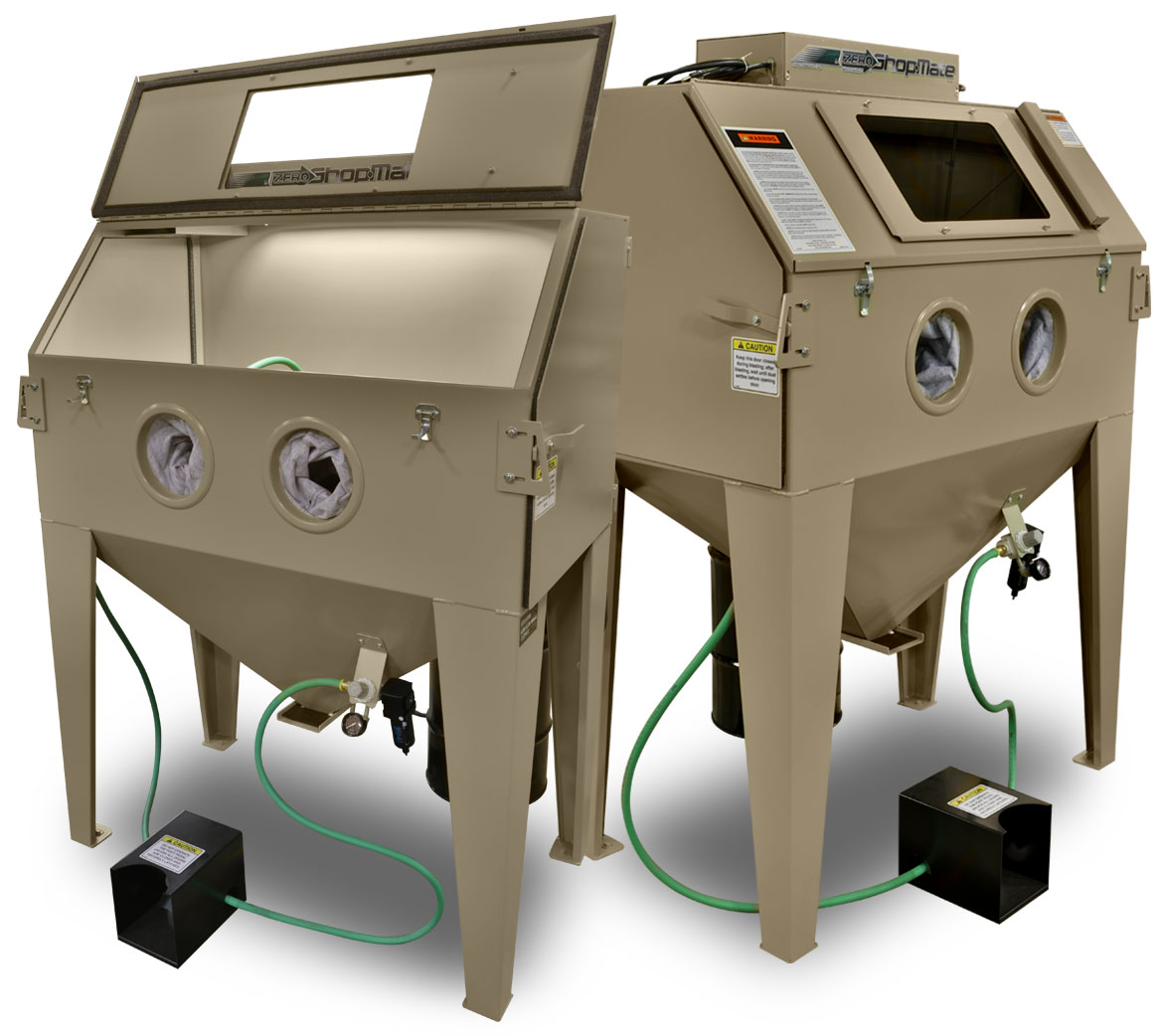

Clemco is dedicated to delivering excellence in abrasive blasting for a broad range of customers, including those that are new to blasting or have limited needs for blasting in their operations. Performance, versatility and return on investment are critical for these customers, yet most of the entry level blast cabinets in the marketplace sacrifice quality to achieve lower cost.

Our ShopMate entry-level blast cabinets feature many of the same features and benefits found in our other blast cabinets, which enables them to provide the same dependable performance that our other industry-leading cabinets deliver.

Productivity

Unscheduled maintenance, inconsistent blasting quality and difficult to use equipment can all contribute to inefficient production team performance. Our economy blast cabinets provide solutions to these challenges including:

- Quick and accessible spring-operated media drain to change and refresh media efficiently

- Simple operation utilizing a pneumatic foot pedal

- A cabinet air regulator to set and maintain ideal air pressure

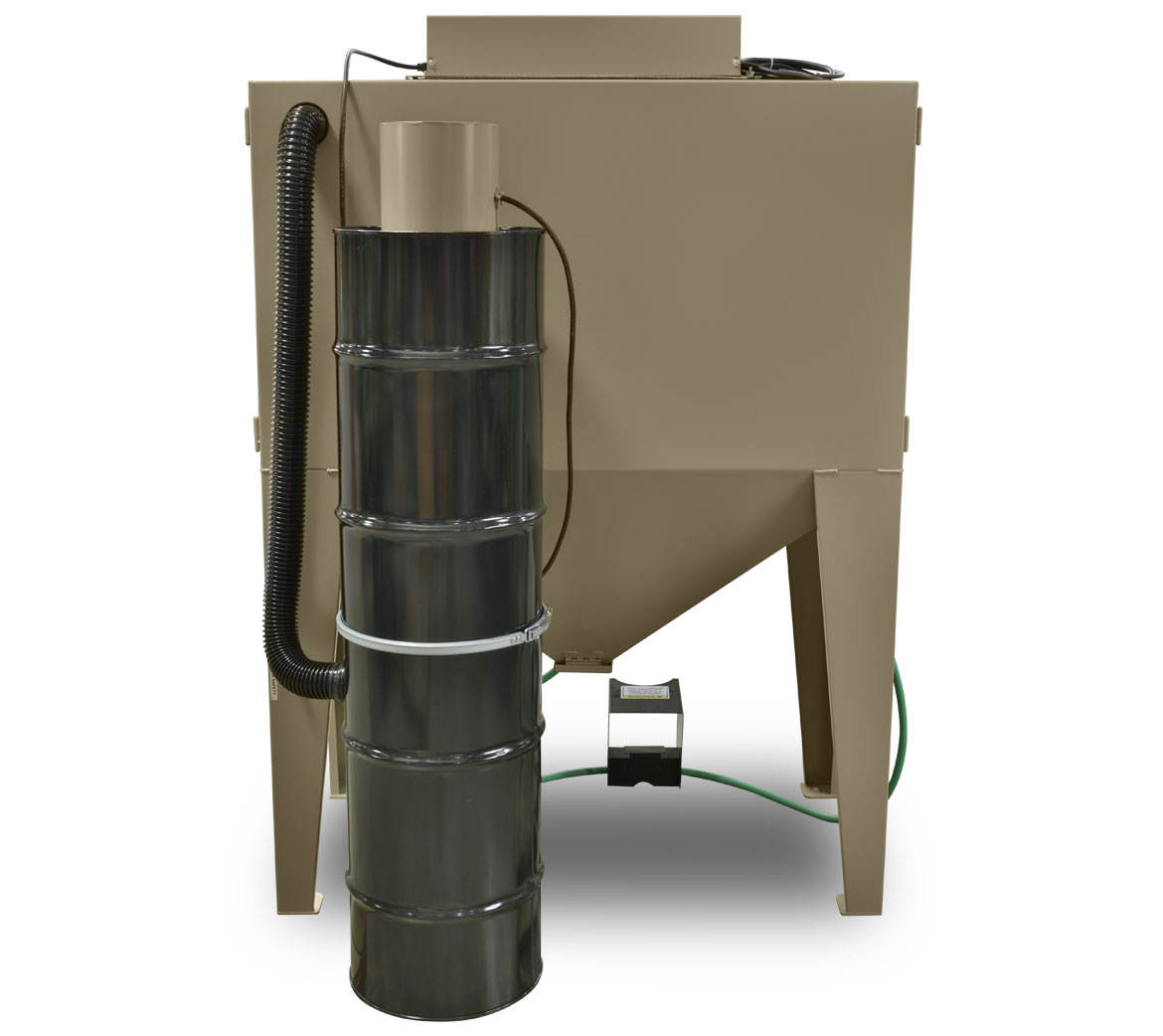

- Dust collection system and protective window film to maximize visibility inside of cabinet

Versatility

Many production environments have fixed space and process limitations. ShopMate cabinets offer superior flexibility to easily fit in among other equipment and adapt to most production processes thanks to these advantages:

- Front load and side load options for accommodating a wide range of parts

- Flexibility to utilize different media types to fit many applications

- Small footprint for flexible placement

Return on Investment

Purchasing abrasive blasting equipment that won’t be used on a full-time basis can be difficult to justify financially, but ShopMate can achieve a fast return on investment that to its:

- High-performance BNP suction gun for best blast performance

- 14 ga. steel construction to stand up to harsh blasting

- Entry level blast cabinet pricing

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.