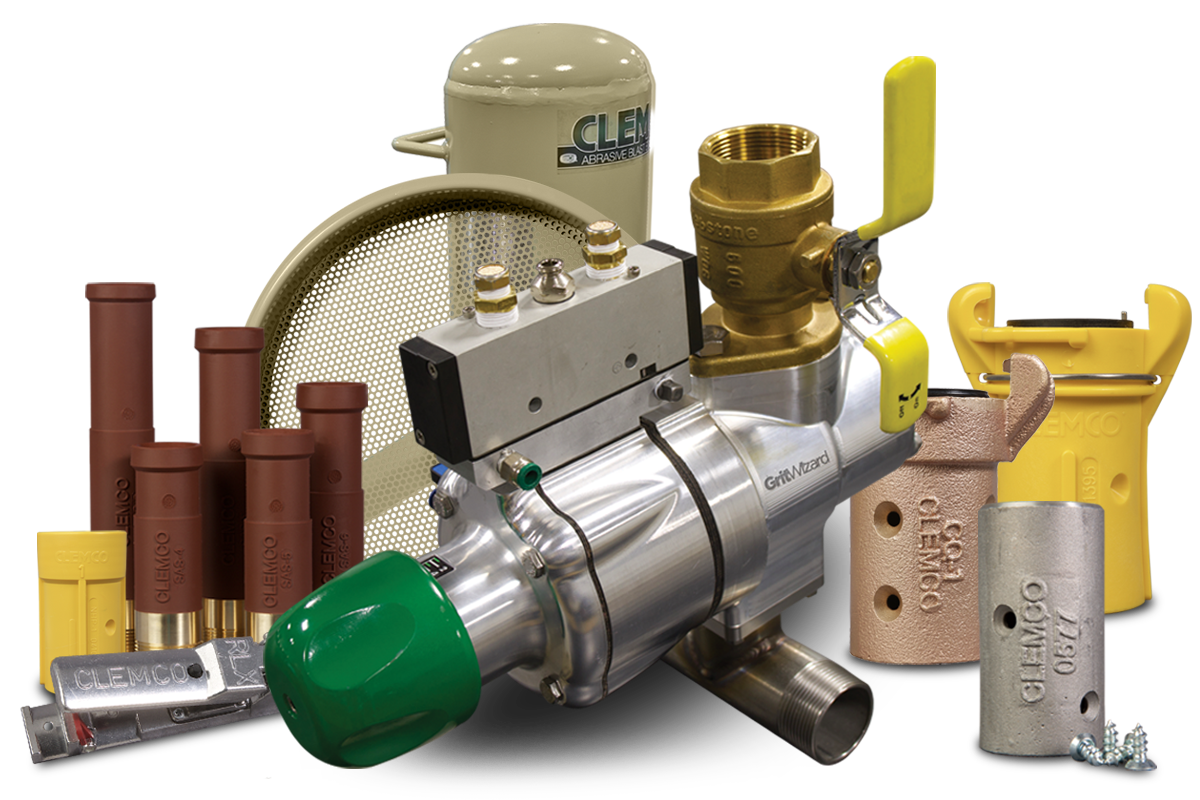

Abrasive Metering Valves, Remote Controls, Blast Nozzles, Blast Hose, Couplings, Moisture Separators, and More

It’s more than the blast machine. In order to blast safely and productively, and to minimize maintenance expenses and unplanned downtime, you need to stock the spares and accessories that your operators require for their abrasive blasting applications. The correct blast hose, metering valve,

blast nozzle, moisture separator, and other accessories—OEM designed to original specifications— can make or break your blasting operation. So don’t break it. Make it, with Clemco OEM spares and accessories.

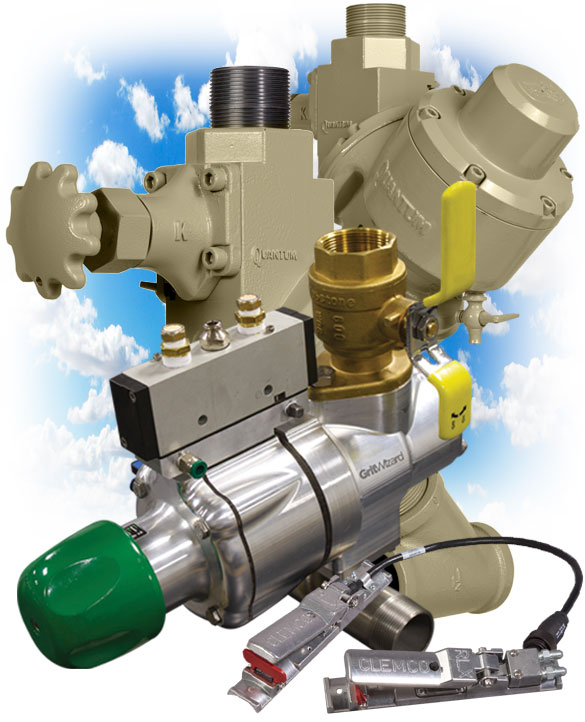

Abrasive Metering Valves and Remote Control Systems

They’re the two most critical components of a blast machine: the metering valve and remote controls. The metering valve enables operators to precisely dial-in their media-air mix for maximum productivity. Remote controls are an OSHA-required safety accessory that allow operators to safely start and stop their blast machines from controls located at the blast nozzle. Clemco offers a variety of abrasive metering valves and remote controls to ensure that you have the equipment to keep your crew productive and on schedule without unplanned downtime.

- Pneumatic Metering Valves – For pressure-release or pressure-hold applications. Clemco Pneumatic Metering Valves range in capabilities from specialty valves for specific media and pot designs, to workhorse valves that handle all common media. The three pneumatic valves come equipped with abrasive cutoff capabilities that enables operators to shut off abrasive flow during blasting.

- Manual Metering Valves – For pressure-release applications. Five manual valves offered, from specialty valves for specific media and pot designs, to workhorse valves that handle expendable mineral and slag abrasives, to valves that meter all common media.

- Remote Control Systems

- Pneumatic – Use with up to 100 ft of blast hose.

- Electric – Use with more than 100 ft of blast hose or when blasting in freezing temperatures.

Nozzles and Nozzle Holders

It’s unavoidable. Nozzles wear out. As the orifice of a nozzle wears and then expands, it needs more air volume to maintain the necessary air pressure for an application. Aside from increasing air consumption, this inevitable wear decreases a nozzle’s service life and performance, and increases media consumption. Clemco offers a variety of nozzles and nozzle holders designed for the requirements of different application so that your abrasive blasting operation remains profitable and productive.

- Long Venturi Nozzles – For high-production blasting with wide blast patterns.

- Short Venturi Nozzles – For high-production blasting in small or confined spaces.

- Straight-Barrel Nozzles – When blasting close to a blast surface, with blast cabinets or small blast machines, or when blasting objects that have detailed or intricate surfaces.

- Side-Angle Nozzles – For awkward or extremely tight blast angles such as inside pipes or in crevices of structural steel.

- Nozzle Holders: Nylon and Aluminum – Lightweight designs for reducing operator fatigue.

Blast Hose, Couplings, and Safety Cables

The blast hose you need depends on the job at hand. You could be working in the field with your blast machine a few yards from the surfaces being blasted, or you could need multiple lengths of hose on a worksite with vehicle traffic. Besides the blast hose, you also need the right couplings, gaskets, and safety cables to get the job done safely and productively. Clemco has you covered with a full line of these accessories.

- Blast Hose – Three styles to meet your blasting needs:

- Supa – Lightweight and mobile.

- 2-Braid – Thicker outer wall and sturdier for industrial settings.

- 4-Ply – Thickest outer wall and most durable. Can even resist occasional light vehicle traffic without collapsing.

- Couplings – Manufactured from three different materials to meet your blasting needs:

- Nylon – Lightweight to reduce operator fatigue.

- Aluminum – Also lightweight, but better for when blasting vertically as when on scaffolding.

- Brass – Most durable.

- Safety Cables – Best protection against injury from a whipping hose should hose separation occur. Available in three sizes.

Media Screens, Blast Machine Covers, Coalescent Filters, Moisture Separators, and Beacon Blast Lights

It’s the little things that can give you an edge in productivity . . . and prevent downtime. Mositure and debris in your machine’s air line can mean unneccasary wear and unplanned maintence in the field, so Clemco offers media screens and blast machine covers, as well as coalescent filters and moisture seperators. We also offer Beacon Blast Lights for increased visbility in dark workplaces.

- Media Screens – Prevent large debris in media from entering your blast machine and creating blockages.

- Blast Machine Covers – Keep rain, snow, and moisture from unexpected weather changes from entering your blast machine and creating media blockages.

- Coalescent Filters – Remove water from compressed air supplies to prevent clumped media blockages. Two models available: inline for one blast machine and freestanding for multiple blast machines.

- Moisture Separators – Inline device installed before an inline coalescent filter to remove even more moisture.

- Beacon Blast Light – Powerful 860-lumen LED light that attaches to the end of a blast hose. Increases operator productivity by increasing visibility.

For More Information

If you’re eager to learn more, simply complete the brief form below and our team of knowledgeable experts will be in touch with you. We sincerely appreciate your interest and look forward to connecting with you soon.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.