Avoid Unplanned Downtime, Ensure Safety, and Keep Productivity High

Quality matters. The quality of your work, of your blast machines, and of their replacement parts and spares. Clemco manufactures OEM blast hose, couplings, and safety cables replacement parts and spares, designed to the specifications of your Clemco blast machines. These accessories help prevent accidents on the job site, unplanned downtime, and hits to your productivity, all of which can be caused by worn components. Protect the safety of your operators, protect your reputation for quality work, by using Clemco OEM blast hose, couplings, and safety cables.

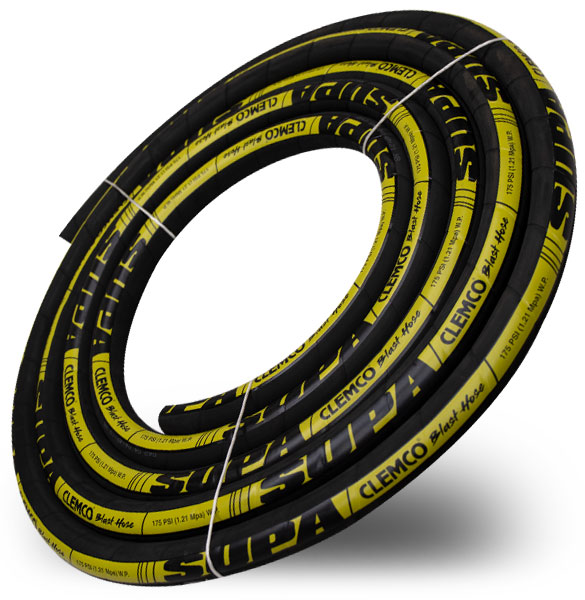

Abrasive Blast Hose

The blast hose you need depends on the job site and the application. You could be working in the field with your blast machine right alongside the target surface, or you could be set up more than 100 ft from the blast area in an industrial setting with vehicle traffic. Whatever the situation, Clemco has the blast hose for your job site and application:

- Supa – Lightweight, mobile blast hose less likely to fatigue operators. Perfect for operator whip hoses or short runs of hose from the blast machine.

- 2-Braid – Thicker outer wall and sturdier than Supa Blast Hose, yet still flexible. Designed for industrial settings where external scuffing can be expected.

- 4-Ply – The most durable Clemco Blast Hose because of its extra-thick outer wall. Designed for long runs of hose in industrial settings. Resistant to scuffing caused by dragging and can even resist occasional light vehicle traffic without collapsing.

Blast Hose Couplings

Blast hose couplings provide secure seals between lengths of blast hose and to hookups to blast machines, preventing air and media leakage. In doing so, blast hose couplings promote safety and productivity. Clemco offers blast hose couplings manufactured with different materials to fit your applications’ requirements:

- Nylon – Lightweight to reduce operator fatigue and features a built-in lock spring to eliminate the need for safety pins.

- Aluminum – Lightweight to reduce operator fatigue. Helpful when operators need to hold sections of blast hose, as when on scaffolding or in other situations when blast hose must be held vertically.

- Brass – The most durable coupling material, but heavier than nylon or aluminum. Ideal for long runs of blast hose that frequently are dragged and moved throughout a job site.

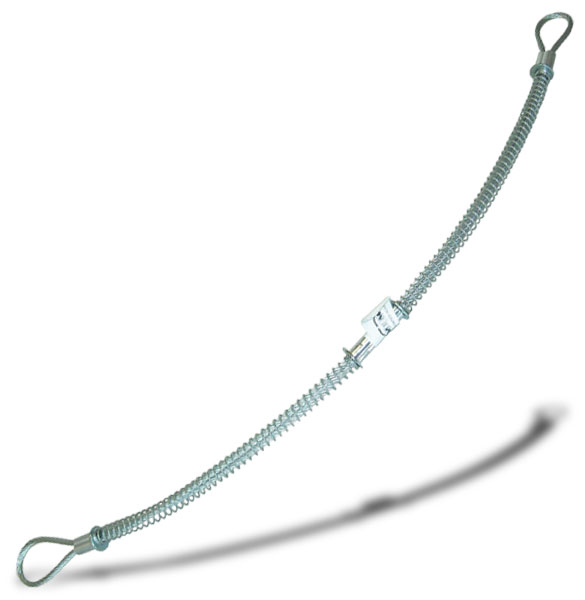

Blast Hose Safety Cables

A coupling failure could shut down your operation and cause serious injury to operators. However, safety cables are a simple, effective, and inexpensive protection against coupling failure from a whipping hose should hose separation occur. Quick to install and easy to remove. Clemco offers safety cables to fit the outer diameter (OD) of all commonly sized blast hose:

Sizes

- 1/2” to 1-1/4” OD Hose

- 1-1/2” to 3” OD Hose

- 1-1/2” to 4” OD Hose

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.